Troy-Bilt Horse Tiller Operation Manual - Page 30

Adding Gear Oil to the PTO Power Unit Transmission - replacement engine

|

View all Troy-Bilt Horse Tiller manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 30 highlights

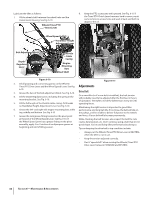

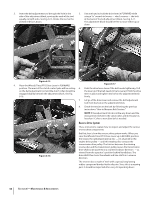

For dipsticks With 'Check Cold' Marking (Cold means 2 hours have passed since the tiller was used.) 1. Move the tiller to level ground. 2. Pull the Depth Regulator Lever back, then push it down all the way (to engage its top notch). 3. Place a sturdy support under the engine to prevent the tiller from tilting too far. 4. Now slide three pieces of 2" x 4" lumber underneath the drag bar - raising the drag bar about 4-1⁄2" above ground. This elevation allows an accurate "cold" gear oil reading . 5. Wait two hours with tiller elevated (allow more time if temperature is below 40ºF). 6. Loosen and remove the transmission dipstick on the back of the tine shield. See Fig. 6-7. Wipe it clean with a rag. 7. Hold the dipstick so its markings face to the rear of tiller. Lower it straight down into the sump hole to touch the drive shaft inside. See Fig. 6-7. Don't force or try to thread it back in; an incorrect reading will result. 8. Remove the dipstick and check the oil level. It should be anywhere within the crosshatched area or even slightly above the Max marking. If correct, replace the dipstick and remove the boards used as props. 9. If the oil level was low, gear oil must be added before using the tiller. See Adding or Changing Gear Oil. For Dipsticks With Hot/Cold Markings 1. Move the tiller to level ground. 2. Pull the Depth Regulator Lever back, then push it down all the way (to engage its top notch). 3. Place a sturdy support under the engine to prevent the tiller from tilting too far. 4. Cold reading (preferred method): (Two hours has passed since the tiller was used.) Place a 2" x 4" board (on edge) under the drag bar - raising the tiller and drag bar about 3-1⁄2" above ground. Hot reading: (Tiller was operated for more than 30 minutes within the past hour.) Do not use the wood prop to elevate the tiller. 5. Follow Steps 4, 5 and 6 given for the other dipstick type. 6. Remove the dipstick and check the level. It should be within or above the "Cold" range marking if taking a cold reading. If taking a hot reading, the level should be within or slightly above the "Hot" range. 7. If the level is incorrect, see Adding or Changing Gear Oil. Adding or Changing Gear Oil For partial fill-ups (just a few ounces or less), use SAE 140, SAE 85W-140, or SAE 80W-90 weight gear oil with an API rating of GL-4 or GL-5. For full replacement, use SAE 140 or SAE 85W-140 gear oil with an API rating of GL-4 only. (At the factory, SAE 85W140 weight gear oil is used.) NOTE: Do not use automatic transmission fluid or engine oil. They are too light in weight and will result in transmission damage. NOTE: The gear oil does not need to be changed. Do so only if you know, or suspect, it is contaminated with dirt, sand or other foreign particles. Gear oil is available at authorized dealers and most service stations, power equipment centers, or farm/heavy equipment outlets. Capacities: The Power Unit transmission holds approximately 60 ounces and the Tine Attachment transmission holds approximately 12-1⁄2" ounces. Adding Gear Oil to the PTO Power Unit Transmission 1. Do steps 1 and 2 of Checking the Power Unit Oil Level. 2. Using a 3⁄4" wrench (or socket), remove the bolt securing the handlebar base to the top of the transmission (prop the handlebars first to prevent them from falling). Then, unplug the Forward Interlock wire harness receptacle at the bottom of the handlebars. Set the handlebar base and bolt aside on a clean surface. The bolt hole in the top of the transmission is the gear oil fill hole. See Fig. 6-7. 3. Slowly pour gear oil through a clean funnel into the transmission. Stop when gear oil begins to flow from the oil level check hole on the left side of the transmission. See Fig. 6-7. 4. Reinstall the oil level check plug. Tighten it securely. 5. Reinstall the handlebars using the mounting bolt previously removed. Align the handlebars so they point straight backwards, not at an angle. Then tighten the mounting bolt securely. 6. Reconnect the Forward Interlock wire harness to the receptacle. Be certain it's secure. 7. Test the operation of the Forward Interlock Safety System. See Forward Interlock System on the next page. Draining and Filling the PTO Power Unit Transmission 1. Place a shallow pan under the transmission gear oil drain plug. See Fig. 6-8. Gear Oil Fill Hole Oil Level Check Plug Gear Oil Drain Figure 6-8 2. Remove the oil level check plug with a 3⁄8" wrench. This vents the transmission for faster oil draining. 30 Section 6- Maintenance & Adjustments