Whirlpool ECKMF94 Installation Guide - Page 26

The modular, ice maker, service, sheet

|

UPC - 050946418711

View all Whirlpool ECKMF94 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 26 highlights

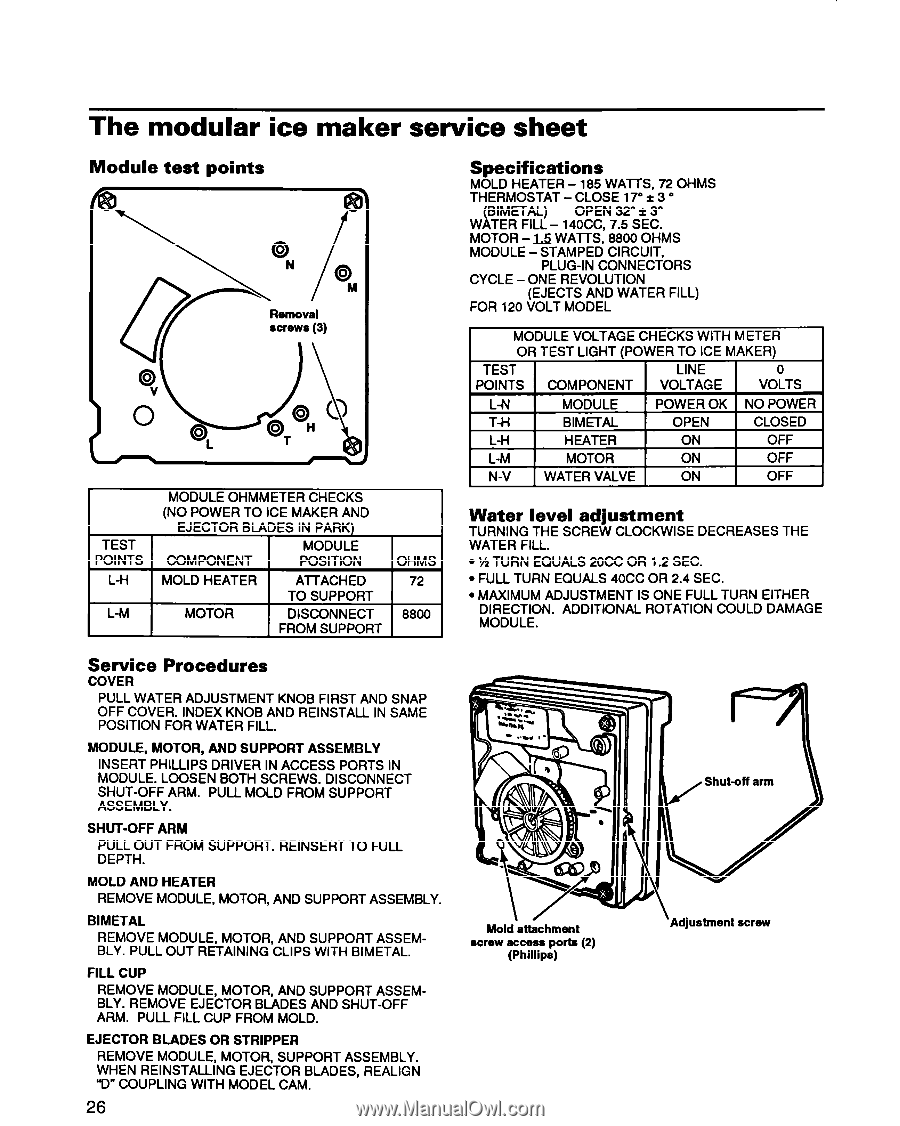

The modular ice maker Module test points Removal wrewe (3) service sheet Specifications MOLD HEATER - 185 WAllS, 72 OHMS THERMOSTAT - CLOSE 17" * 3 o (BIMETAL) OPEN 32" f 3" WATER FILL - 14OCC, 7.5 SEC. MOTOR -u WAlTS, 8800 OHMS MODULE -STAMPED CIRCUIT, PLUG-IN CONNECTORS CYCLE - ONE REVOLUTION (EJECTS AND WATER FILL) FOR 120 VOLT MODEL MODULE VOLTAGE CHECKS WITH METER OR TEST LIGHT (POWER TO ICE MAKER) TEST I I LINE I 0 MODULE OHMMETER CHECKS (NO POWER TO ICE MAKER AND EJECTOR BLADES IN PARK) TEST 1 I MODULE I Service Procedures COVER PULL WATER ADJUSTMENT KNOB FIRST AND SNAP OFF COVER. INDEX KNOB AND REINSTALL IN SAME POSITION FOR WATER FILL. MODULE, MOTOR, AND SUPPORT ASSEMBLY INSERT PHILLIPS DRIVER IN ACCESS PORTS IN MODULE. LOOSEN BOTH SCREWS. DISCONNECT SHUT-OFF ARM. PULL MOLD FROM SUPPORT ASSEMBLY. SHUT-OFF ARM PULL OUT FROM SUPPORT. REINSERT TO FULL DEPTH. MOLD AND HEATER REMOVE MODULE, MOTOR, AND SUPPORT ASSEMBLY. BIMETAL REMOVE MODULE, MOTOR, AND SUPPORT ASSEMBLY. PULL OUT RETAINING CLIPS WITH BIMETAL. FILL CUP REMOVE MODULE, MOTOR, AND SUPPORT ASSEMBLY. REMOVE EJECTOR BLADES AND SHUT-OFF ARM. PULL FILL CUP FROM MOLD. EJECTOR BLADES OR STRIPPER REMOVE MODULE, MOTOR, SUPPORT ASSEMBLY. WHEN REINSTALLING EJECTOR BLADES, REALIGN "D" COUPLING WITH MODEL CAM. 26 L-M MOTOR ON OFF N-V WATER VALVE ON OFF Water level adiustment TURNING THE SCRE'jv CLOCKWISE DECREASES THE WATER FILL. . 'h TURN EQUALS 20CC OR 1.2 SEC. l FULL TURN EQUALS 40CC OR 2.4 SEC. . MAXIMUM ADJUSTMENT IS ONE FULL TURN EITHER DIRECTION. ADDITIONAL ROTATION COULD DAMAGE MODULE. \ / Mold attachment screw access ports (2) (Phillips) \ Adjustment screw