Brother International BAS-342E Instruction Manual - English - Page 45

Wiper, adjustment, Adjustment, pressure

|

View all Brother International BAS-342E manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 45 highlights

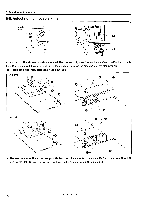

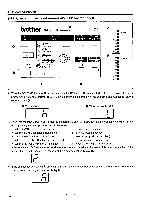

9. Standard adjustments 9-9. Wiper adjustment • For vertical wiper (standard) 0 0 112 mm 0 approx. 2 mm 15 mm Fig. A 1. When the thread wiper solenoid plunger 0 is driven to the full stroke, the wiper 0 should be 15 mm in front of the needle center. Loosen screws 0 and shift the entire solenoid bracket 0 up or down to adjust. The standard height from the solenoid bracket 0 bottom to the needle plate top is approximately 112 mm. 2. When the wiper 0 is operated and aligned with the center of the needle bar, the distance from the wiper 0 to needle tip should be approximately 2 mm. Loosen screw 0 and move the wiper 0 in or out to adjust. As shown in Fig. A, make sure the wiper 0 does not strike the presser foot 0 or needle. NOTE Check that the wiper 0 is not touching the finger guard. 9-10. Adjustment of air pressure c Ill 1. Air pressure should be 0.49 MPa [5 kg/cm2]. The air pressure can be adjusted by pulling up andturning the control knob 0 on the integrator 0. After adjustment is complete, push the control knob 0 downward to lock it. 2. If water stands in the bottle of the integrator 0, turn the drain cock 0 in the direction indicated by an arrow to drain the water. NOTE Open the air cock 0 slowly. -CT BAS-341E • 342E 38