Brother International BAS-342E Instruction Manual - English - Page 60

After

|

View all Brother International BAS-342E manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 60 highlights

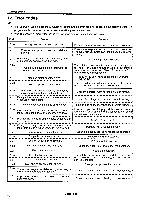

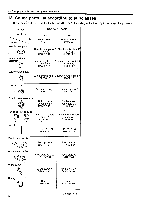

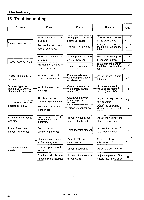

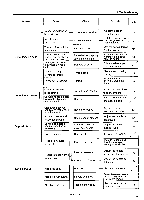

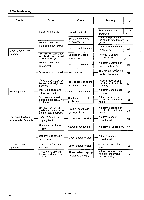

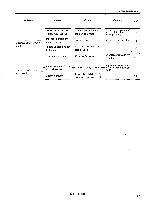

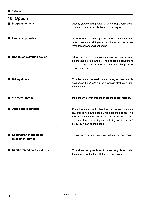

14. Notes on the processing and production of plate blanks 14. Notes on the processing and production of plate blanks BAS-341E BAS-342E AfterPlate blank processing Plate blank After processing A * Chamfer other corners of the reverse side of the plate blank with a thickness of 0.3c or thicker, and finish the corners with fine sand paper. Please carry out tne following points to chamfer the reverse side of the plate blank when using the plate blank for any supplementary processing of material. * Cross-section A-A' 15° Use fine sand paper or similar material to acquire a smooth 0.7 mm surface for this section. - Point at which to use sand paper, etc. 0.3C BAS-341E • 342E 53

14.

Notes

on

the

processing

and

production

of

plate

blanks

14.

Notes

on

the

processing

and

production

of

plate

blanks

BAS

-341E

After

processing

Plate

blank

BAS

-342E

A

Plate

blank

After

processing

*

Chamfer

other

corners

of

the

reverse

side

of

the

plate

corners

with

fine

sand

paper.

Please

carry

out

tne

following

points

to

chamfer

the

reverse

supplementary

processing

of

material.

*

Cross-section

A

-A'

15°

Use

fine

sand

paper

or

similar

material

to

acquire

a

smooth

0.7

mm

surface

for

this

section.

blank

with

a

thickness

of

0.3c

or

thicker,

and

finish

the

side

of

the

plate

blank

when

using

the

plate

blank

for

any

-

Point

at

which

to

use

sand

paper,

etc.

0.3C

BAS

-341E

•

342E

53