Brother International BAS-342E Instruction Manual - English - Page 66

Options

|

View all Brother International BAS-342E manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 66 highlights

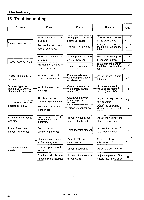

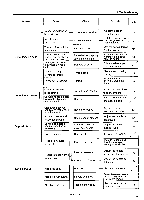

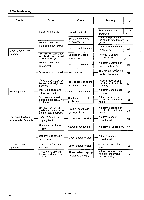

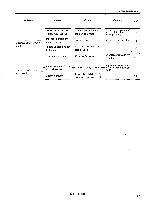

■ Thread breakage detector device 16. Options Available as rotary type or fiber type, stops sewing when a thread breakage is detected and warns the operator. ■ Needle coder device This is a pneumatic-type needle cooler which prevents the thread breaking due to heat. It is particularly useful when sewing thicker materials at high sewing speeds. ■ OT Presser Use according to particular sewing needs in order to provide an even clamping force. ■ Soft presser At the first stage, the work clamp applies only a spring force so that the material can be positioned. Then at the second stage, air pressure provides a full clamping force. ■ Cassette presser This allows the operator to hold two clamps so that the preparation for the next operation can be carried out while sewing is in progress. Overlapping operations are thus possible, which can greatly boost productivity. ■ Play prevention work clamp This work clamp prevents any play from occurring in the clamp. ■ Thread wiper the side Wipes the upper thread away to the side when an inner clamping device is being used. ■ Air wipper device The thread wiper is driven by a pneumatic cylinder. ■ 2-step thread tension device Allows the upper thread tension to be switched between two settings at any position desired by using the programmer. * Refer to the separate Parts Book for details. BAS-341E • 342E 59