Brother International HE-800A Instruction Manual - English - Page 107

Upper thread run out - service manual

|

View all Brother International HE-800A manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 107 highlights

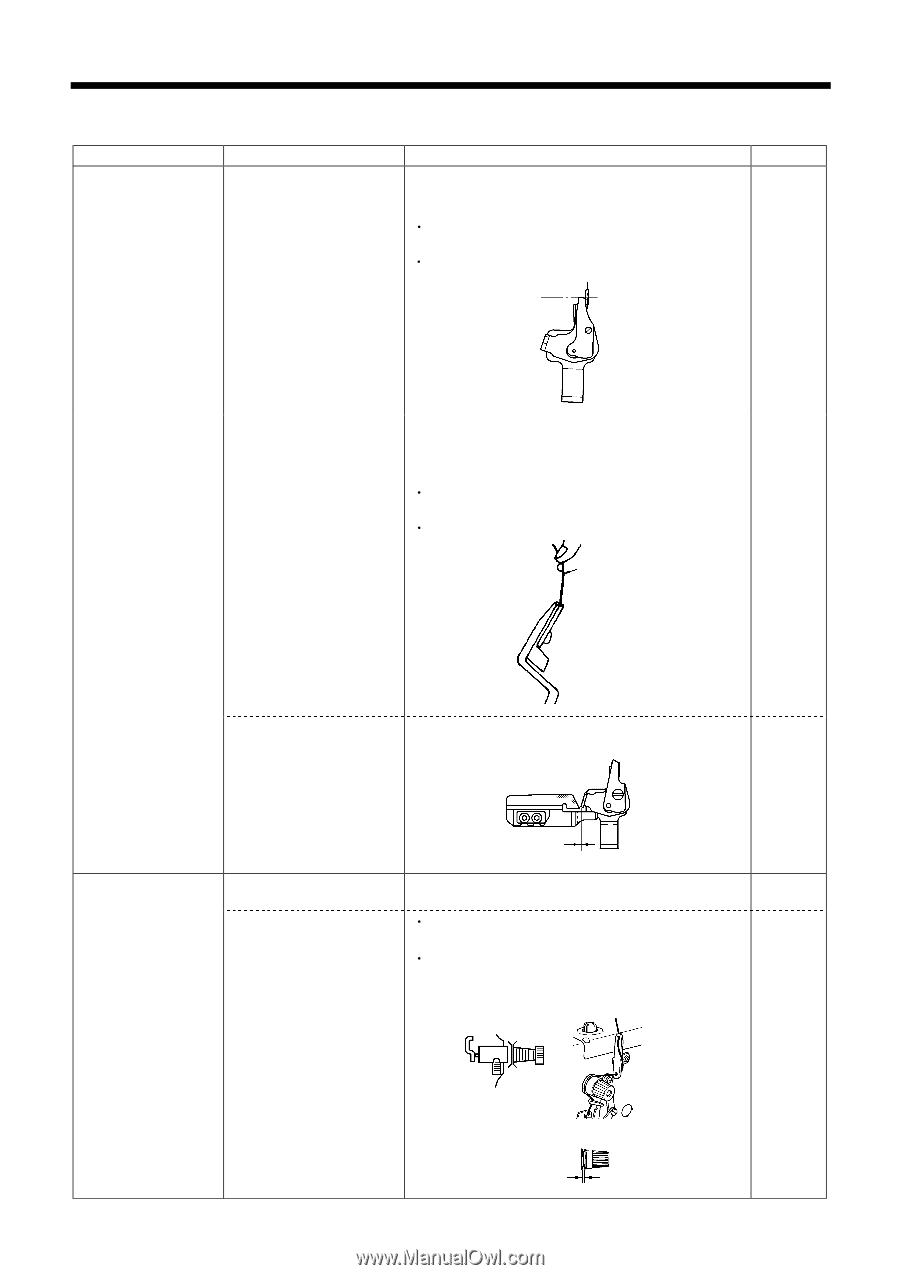

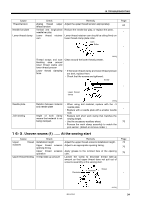

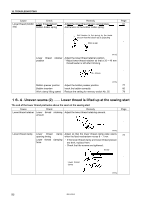

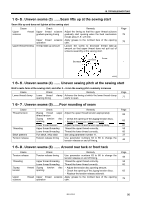

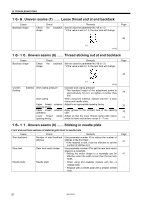

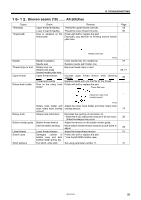

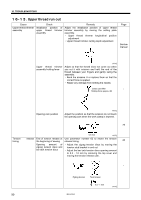

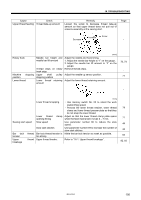

16. TROUBLESHOOTING Upper thread run out Cause Upper thread trimmer assembly Check Installation position of upper thread trimmer assembly Remedy Adjust the installation position of upper thread trimmer assembly by moving the setting plate assembly. Upper thread trimmer longitudinal position adjustment Upper thread trimmer cutting depth adjustment Page Service manual Upper thread trimmer assembly holding force 4005Q Adjust so that the thread does not come out when you cut it with scissors and hold the end of the thread between your fingers and gently swing the assembly. Bend the scissors U or replace them so that the correct force is applied. Repair any damage from striking the needle. Cotton yarn #60 - Holding force approx. 2N Opening cam position 4006Q Adjust the position so that the scissors do not touch the opening cam when the work clamp is lowered. 76 0.5 mm 4007Q Tension timing release End of tension release at Use parameter number 63 to retard the tension the beginning of sewing release timing. 44 Opening amount of zigzag tension discs and bar tack tension discs Adjust the zigzag tension discs by moving the tension stud bracket in and out. Adjust the bar tack tension discs opening amount to 0.5 - 1.0 mm by removing the top cover and moving the tension release cam. - Zigzag tension Tack tension 0.5 - 1 mm 4008Q 99 HE-800A