Canon PC740 Service Manual - Page 107

PC720/7401750M0

|

View all Canon PC740 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 107 highlights

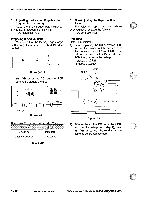

OPERATIONS AND TIMING= 9) Make a copy, and make sure that it is free of fogging yet its text is dark enough. • If the copy is foggy or the text density is too light, repeat starting with step 1). • If no change is noted in the results after re-adjustment, make further adjustments using the density correction switch (SW101). 4. Adjusting the Leading Edge NonImage Width Adjust the leading edge non-image width whenever you have replaced the following: • DC controller PCB Preparing for Adjustment Make sure the leading edge non-image width is 2.0 ±1.0 mm when the Test Chart is copied. 0 SW101 Figure 3-707 2.0± 1.0 [aim] Figure 3-708 1) Turn VR105 on the DC controller PCB so that the standard is met. O Jpal]Ova V2104 V2205 E 221101 22002 18 V0102 V0103 J105 I 12 VR105 Figure 3-709 .009 O " Direction of VR105 and Leading Edge Non-Image Width . Direction Width Clockwise Increases Counterclockwise Decreases Table 3-703 COPYRIGHT © 1994 CANON INC. CANON PC720/7401750M0 RED AUG.1994 PRINTED IN JAPAN (IMPRIME AU JAPON) 3 - 67