Dell PowerConnect B-RX8 Installation Guide - Page 70

Unpacking a BigIron RX-32 switch, Installation location, Uncrating the BigIron RX-32 chassis

|

View all Dell PowerConnect B-RX8 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 70 highlights

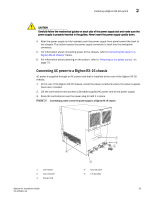

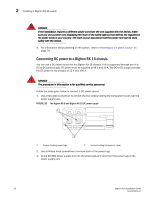

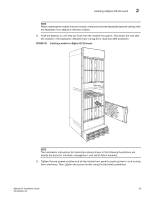

2 Installing a BigIron RX-32 switch Installation location Before installing the switch, plan its location and orientation relative to other devices and equipment. For cooling purposes, allow a minimum of six inches of space between the sides, front, and the back of the chassis and walls or other obstructions. If a chassis is installed within a perforated enclosure, the perforations must have openings of at least 60 percent of the surface. Since you will be using a mechanical lift to move and install the chassis, make sure you allow enough working room. NOTE Make sure your site provides 200-240 AC power. Unpacking a BigIron RX-32 switch The BigIron RX-32 switch ships with several items. Review the list below, and verify the contents. If any items are missing, contact the place of purchase: • BigIron RX-32 chassis with the card slots empty, and covered with upper and lower shipping panels (refer to uncrating instructions next) • The appropriate number of interface modules, switch fabric modules, management modules, and power supplies shipped separately • A total of 32 slot blanks shipped separately • Rack mount kit, including two L-shaped brackets and mounting screws NOTE You must provide standard #12-24 pan-head screws for mounting the BigIron RX Series chassis into a rack. • Insertion or extraction tool for use with RJ-45 and fiber-optic connectors • CD-ROM containing software images and the user documentation (including this guide) • Warranty card • A 220-240V AC power cable for each AC power supply you purchase from Brocade Uncrating the BigIron RX-32 chassis Before uncrating the chassis, the site should be prepared as described in "Preparing the installation site" on page 57. You will need the following tools: • A forklift or pallet jack to move the chassis while still on the pallet (at least 550-lb limit) • A mechanical lift (at least 350-lb limit) for moving the chassis off the pallet. The ideal configuration is a counterweight base material lift with a metal lift plate installed in place of the forks. The metal plate should be no wider than 17 inches, so that it will fit between the rack mount rails. • A strap to stabilize the chassis while being moved on the mechanical lift • A power drill • A large Phillips screwdriver attachment • A 7/16-inch socket wrench attachment 58 BigIron RX Installation Guide 53-1001811-01