Hitachi NT65MA3 Instruction Manual - Page 19

Regrinding the Driver Blade, Abnormal plunger

|

UPC - 717709011281

View all Hitachi NT65MA3 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 19 highlights

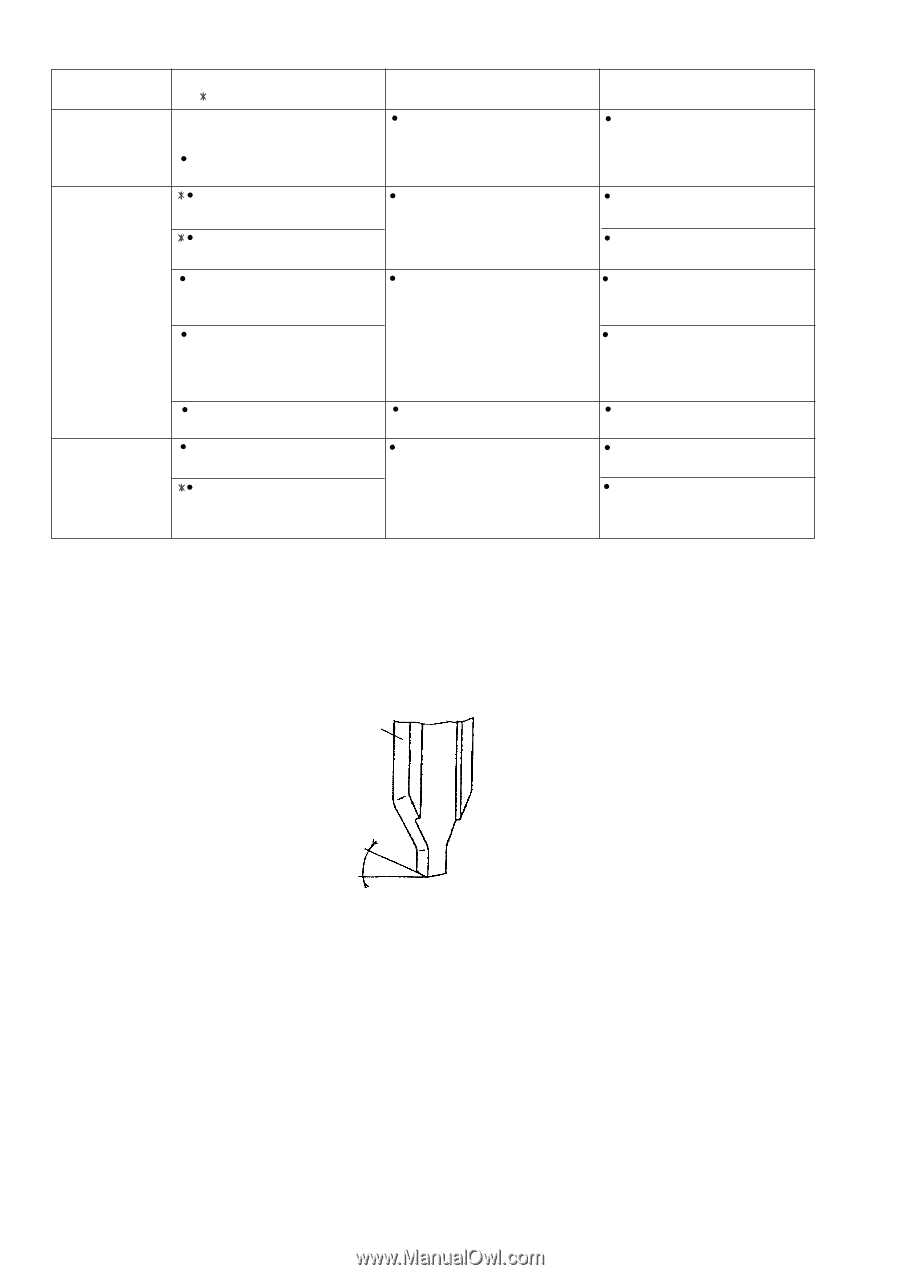

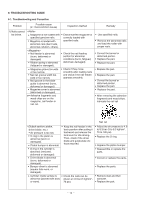

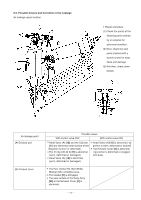

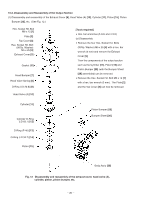

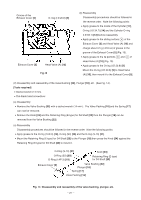

Problem Possible cause ( : most-common cause) 4) Nails jam. (continued) < Driver blade is not returned completely > See item "1) Output section: piston, driver blade, etc." 5) Single actuation mechanism is not possible. O-ring in plunger (A) is worn. O-ring in valve piston (B) is worn. Plunger (A) sliding surface abnormal of valve piston (B) (seized or deformed). Abnormal plunger (A), trigger arm (A), pushing lever (B), and/or body (worn or damaged). The position of a switching device is mistaken. 6) Air keeps blowing from the nose of the blow nozzle. Spring is abnormal (fatigued or damaged). O-ring in the plunger is abnormal (removed, deformed or damaged). Inspection method Perform idle or actual driving to check if the driver blade is returned completely. Disassemble the control valve section, and check the O-ring of plunger (A) and valve piston (B). Check each part for abnormalities (worn, damaged, deformed, etc.) The position of a switching device is checked. Press the button of the blow nozzle to check if it operates smoothly. Remedy See item "1) Output section: piston, driver blade, etc." Replace the part. Replace the part. Replace the part. Replace the abnormal part. A switching device is set to the correct position. Replace the spring. Reassemble or replace the parts. 9-2. Regrinding the Driver Blade The tip of the driver blade should be ground as shown in Fig. 11. To grind with a grinder, gradually grind the tip while cooling the ground area with water to prevent it from being excessively heated. Excessive grinding will rapidly reduce the service life of the driver blade. In such a case, replace the driver blade. Driver blade 3û 30" Fig. 11 --- 16 ---