Hitachi NT65MA3 Instruction Manual - Page 27

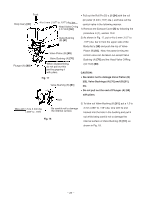

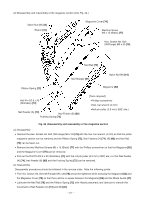

As shown in Fig. 19, install Valve Bushing A, and O-ring I.D 11

|

UPC - 717709011281

View all Hitachi NT65MA3 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 27 highlights

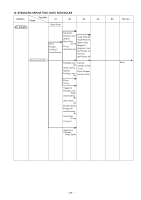

(b) Reassembly Disassembly procedures should be followed in the reverse order. Note the following points: Be extremely careful to prevent the entry of foreign particles into the control valve section. Thoroughly apply grease to the O-ring (I.D 1.8) [69] on Plunger (A) [68], O-ring (S-4) [64], O-ring (I.D 8.8) [63] and O-ring (I.D 11) [66] on Valve Piston (B) [65], and the shaft of Plunger (A) [68] as shown in Fig. 19. As shown in Fig. 19, install Valve Bushing (A) [70] so that the roll pin groove in Valve Bushing (A) [70] will be aligned with the roll pin hole in the Body Ass'y [30]. First, insert a roll pin puller (3 mm (.118") dia.) into the roll pin hole. Then, upon confirming that the puller passes through the hole, drive in the Roll Pin D3 x 28 [54]. If an attempt is made to drive the roll pin with force when the roll pin groove in Valve Bushing (A) [70] is not aligned with the roll pin hole in the Body Ass'y [30], it will damage the periphery of Valve Bushing (A) [70] and prevent disassembly or reassembly. Body Ass'y [30] Apply grease to the stem. Coat the O-ring groove's shaft with grease. Roll pin hole Roll pin groove Roll Pin D3 x 28 [54] Assemble Plunger (A) [68] Valve Bushing (A) [70] Fig. 19 After assembling, check that Plunger (A) [68] moves smoothly. Valve Bushing (A) [70] --- 24 ---