LG LRSC26980TT Service Manual - Page 70

Bad torque for assembling motor - support

|

View all LG LRSC26980TT manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 70 highlights

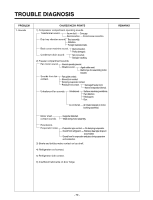

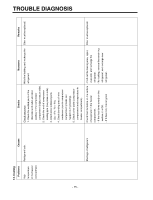

TROUBLE DIAGNOSIS PROBLEM 7. Sounds CAUSE/CHECK POINTS 1) Compressor compartment operating sounds. Transformer sound. Its own fault. -- Core gap. Bad connection. -- Correct screw connection. Drip tray vibration sound. Bad assembly. Distortion. Foreign materials inside. Back cover machine sound. Bad connection. Partly damaged. Condenser drain sound. Not connected. Bad pipe caulking. 2) Freezer compartment sounds. Fan motor sound. Normal operating sound. Vibration sound. Aged rubber seat. Bad torque for assembling motor bracket. Sounds from fan contact. Fan guide contact. Shroud burr contact. Damping evaporator contact. Residual frost contact. Damaged heater cord. Narrow evaporator interval. Unbalanced fan sounds. Unbalanced Surface machining conditions. Fan distortion. Misshappen. Burr. Ice on the fan. -- Air intake (opposite to motor bushing assembly.) Motor shaft contact sounds. Supporter distorted. Tilted during motor assembly. Resonance. Evaporator noise. Evaporator pipe contact. -- No damping evaporator. Sound from refrigerant. -- Stainless steel pipe shape in accumulator. Sound from fin evaporator and pipe during expansion and contraction. 3) Bowls and bottles make contact on top shelf. 4) Refrigerator roof contact. 5) Refrigerator side contact. 6) Insufficient lubricants on door hinge. REMARKS - 70 -