LG LRSC26980TT Service Manual - Page 73

Power, Compressor

|

View all LG LRSC26980TT manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 73 highlights

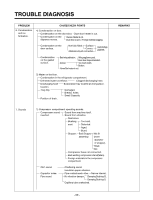

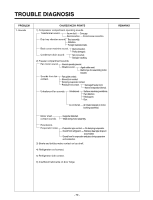

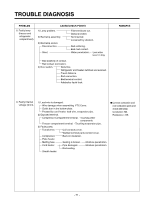

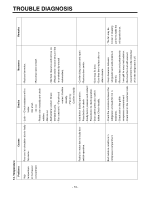

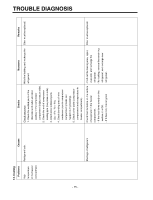

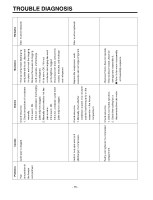

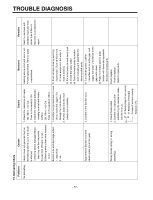

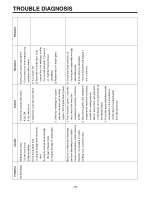

TROUBLE DIAGNOSIS - 73 - 11. Power Problems Causes Checks Measures No power on outlet. - Power cord cut. - Faulty connector insertion. - Faulty connection between plug and adapter. - Check the voltage with a tester. - Check visually. - Check visually. -Replace the components. -Reconnect the connecting parts. -Reconnect the connecting parts. Fuse blows out. - Short circuit by wrong connection. - Low voltage products are connected to high voltage. - Short circuit by insects. - Electricity leakage. - High voltage. - Short circuit of components (tracking due to moisture and dust penetration). - Check the fuse with tester - Find and remove the cause of or visually. problem (ex. short, high voltage, - Check the input voltage with a tester. low voltage). (between power cord and products). - Replace with rated fuse. - Check the resistance of power cord with tester (if it is 0Ω, it is shorted). Remarks - Replace with rated fuse after confirming its specification. I If fuse blows out frequently, confirm the cause and prevent. 12. Compressor Problems Causes Compressor does not operate. - Faulty PTC. - Compressor is frozen. Checks Measures - Check the resistance. Vlaue:∞ is defective. - If compressor assembly parts are normal (capacitor, PTC, OLP), apply power directly to the compressor to force operation. Auxiliary winding OLP Main winding Power It starts as soon as it is contacted. - If resistance is infinite, replace it with new one. - If it is not infinite, it is normal. - Check other parts. - During forced operation: - Operates: Check other parts. - Not operate: Replace the frozen compressor with new one, weld, evacuate, and recharge refrigerant. • Refer to weld repair procedures. Remarks