Stihl MS 150 C-E Instruction Manual - Page 26

Chain Lubricant

|

View all Stihl MS 150 C-E manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 26 highlights

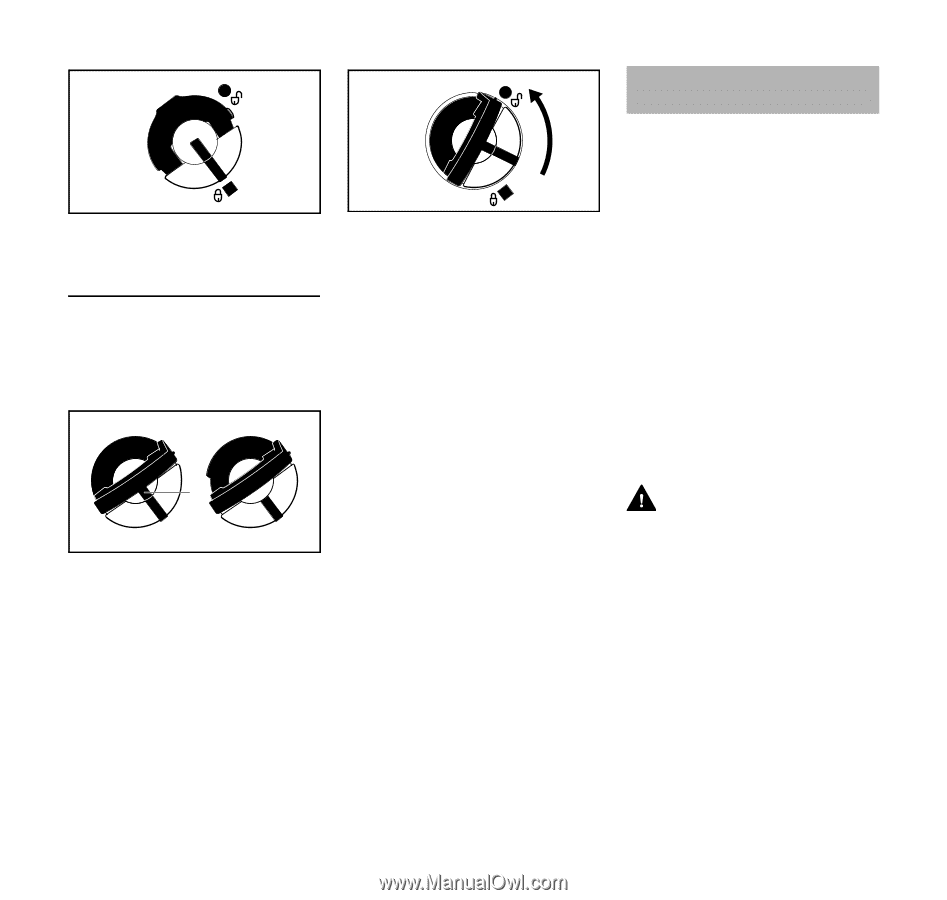

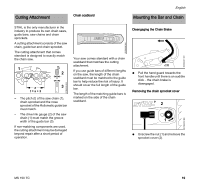

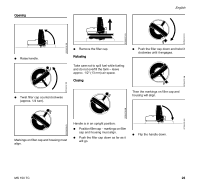

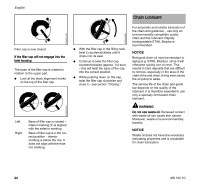

English Chain Lubricant Filler cap is now closed. If the filler cap will not engage into the tank housing The base of the filler cap is rotated in relation to the upper part. N Look at the black alignment marks on the top of the filler cap. 1 Left: Right: Base of filler cap is rotated - interior marking (1) is aligned with the exterior marking. Base of filler cap is in the correct position - interior marking is below the clip. It does not align with the exterior marking. 001BA238 KN 001BA241 KN 001BA239 KN N With the filler cap in the filling neck, twist it counterclockwise until it drops into its seat. N Continue to twist the filler cap counterclockwise (approx. 1/4 turn) - this will twist the base of the cap into the correct position. N While pushing down on the cap, twist the filler cap clockwise and close it - see section "Closing." For automatic and reliable lubrication of the chain and guide bar - use only an environmentally compatible quality chain and bar lubricant. Rapidly biodegradable STIHL Bioplus is recommended. NOTICE Biological chain oil must be resistant to aging (e.g. STIHL Bioplus) since it will otherwise quickly turn to resin. This results in hard deposits that are difficult to remove, especially in the area of the chain drive and chain. It may even cause the oil pump to seize. The service life of the chain and guide bar depends on the quality of the lubricant. It is therefore essential to use only a specially formulated chain lubricant. WARNING Do not use waste oil. Renewed contact with waste oil can cause skin cancer. Moreover, waste oil is environmentally harmful. NOTICE Waste oil does not have the necessary lubricating properties and is unsuitable for chain lubrication. 24 MS 150 TC