Stihl MS 150 C-E Instruction Manual - Page 43

to which the cutter penetrates the wood - equal what f

|

View all Stihl MS 150 C-E manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 43 highlights

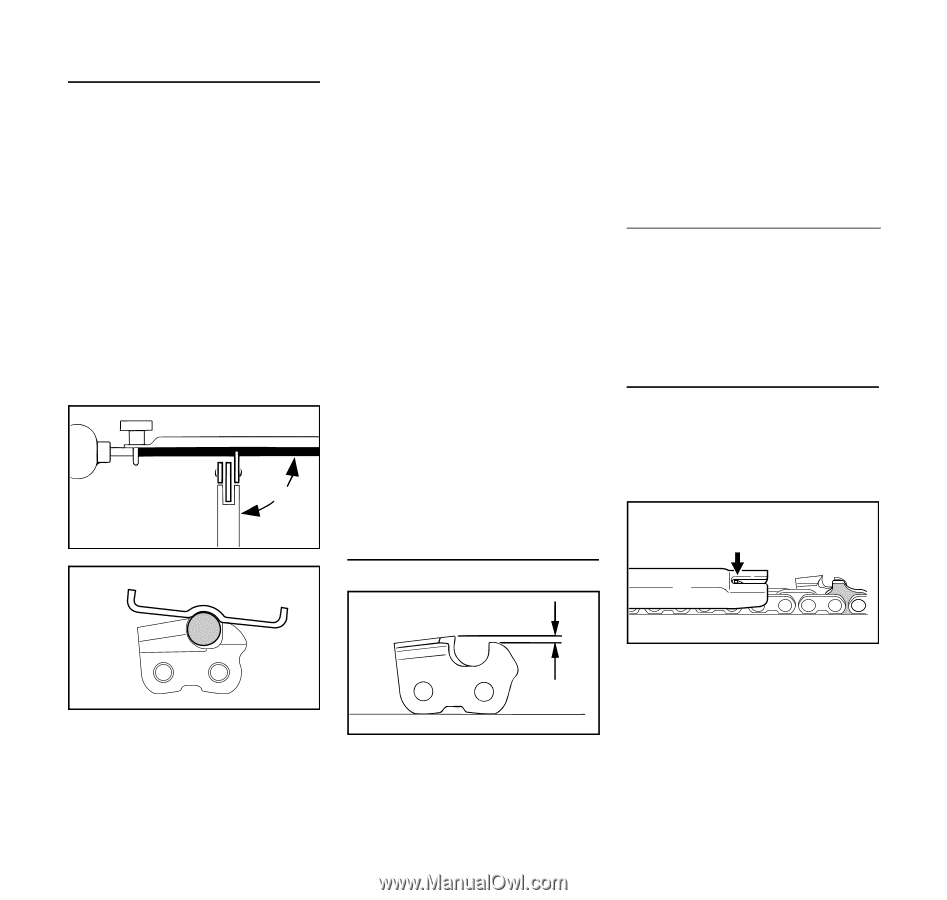

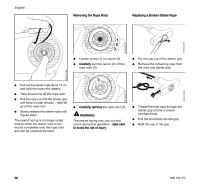

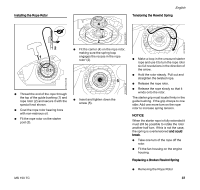

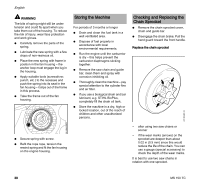

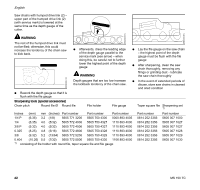

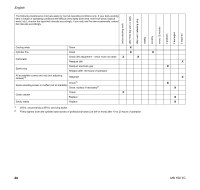

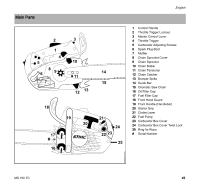

Proper sharpening N Select sharpening tools in accordance with chain pitch N Clamp guide bar if necessary N Block saw chain - push the hand guard forward N To advance the saw chain, pull the hand guard toward the handlebar: The chain brake is disengaged. With the Quickstop Plus chain brake system, additionally press the throttle trigger lockout N Sharpen frequently, removing little material - two or three strokes of the file are usually sufficient for simple resharpening 90° 689BA018 KN markings on the file holder - rest the file holder on the tooth head and the depth gauge N File only from the inside outward N The file only sharpens on the forward stroke - lift the file on the backstroke N Do not file tie straps and drive links N Rotate the file a little periodically in order to avoid uneven wear N To remove file burr, use a piece of hardwood N Check angle with file gauge All cutters must be equally long. With varying cutter lengths, the cutter heights also vary and cause rough running of the saw chain and chain breakage. N All cutters must be filed down equal to the length of the shortest cutter - ideally, one should have this done by a servicing dealer using an electric sharpener Depth gauge setting English a Required distance between depth gauge and cutting edge When cutting softwood outside of the frost season, the distance can be increased by up to 0.2 mm (0.008"). Chain pitch Inches 1/4 P 1/4 3/8 P 0.325 3/8 0.404 (mm) (6.35) (6.35) (9.32) (8.25) (9.32) (10.26) Depth gauge Distance (a) mm (Inches) 0.45 (0.018) 0.65 (0.026) 0.65 (0.026) 0.65 (0.026) 0.65 (0.026) 0.80 (0.031) Lowering the depth gauges The depth gauge setting is lowered when the cutter is sharpened. N Check the depth gauge setting after each sharpening 1 2 N Guide the file: horizontally (at a right angle to the side surface of the guide bar) in accordance with the specified angle - according to the 689BA043 KN a The depth gauge determines the depth to which the cutter penetrates the wood and thus the chip thickness. 689BA023 KN N Lay the appropriate file gauge (1) for the chain pitch on the saw chain and press it against the cutter to be checked - if the depth gauge protrudes past the file gauge, the depth gauge must be reworked 689BA061 KN MS 150 TC 41