Stihl MS 150 C-E Instruction Manual - Page 44

filings or grinding dust - lubricate

|

View all Stihl MS 150 C-E manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 44 highlights

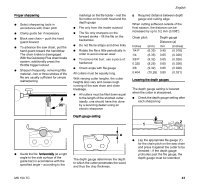

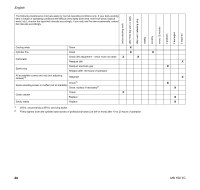

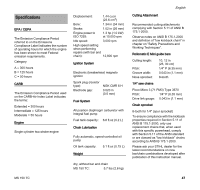

English Saw chains with humped drive link (2) - upper part of the humped drive link (2) (with service mark) is lowered at the same time as the depth gauge of the cutter. 689BA051 KN 689BA044 KN 689BA052 KN WARNING The rest of the humped drive link must not be filed; otherwise, this could increase the tendency of the chain saw to kick back. N Afterwards, dress the leading edge of the depth gauge parallel to the service mark (see arrow) - when doing this, be careful not to further lower the highest point of the depth gauge WARNING Depth gauges that are too low increase the kickback tendency of the chain saw. N Rework the depth gauge so that it is flush with the file gauge Sharpening tools (special accessories) Chain pitch Round file ^ Round file File holder File gauge N Lay the file gauge on the saw chain - the highest point of the depth gauge must be flush with the file gauge N After sharpening, clean the saw chain thoroughly, removing any filings or grinding dust - lubricate the saw chain thoroughly N In the event of extended periods of disuse, store saw chains in cleaned and oiled condition Taper square file Sharpening set 1) Inches (mm) mm (Inches) Part number Part number Part number 1/4 P (6.35) 3.2 (1/8) 5605 771 3206 5605 750 4300 0000 893 4005 1/4 (6.35) 4.0 (5/32) 5605 772 4006 5605 750 4327 1110 893 4000 3/8 P (9.32) 4.0 (5/32) 5605 772 4006 5605 750 4327 1110 893 4000 0.325 (8.25) 4.8 (3/16) 5605 772 4806 5605 750 4328 1110 893 4000 3/8 (9.32) 5.2 (13/64) 5605 772 5206 5605 750 4329 1110 893 4000 0.404 (10.26) 5.5 (7/32) 5605 772 5506 5605 750 4330 1106 893 4000 1) consisting of file holder with round file, taper square file and file gauge Part number 0814 252 3356 0814 252 3356 0814 252 3356 0814 252 3356 0814 252 3356 0814 252 3356 Part number 5605 007 1000 5605 007 1027 5605 007 1027 5605 007 1028 5605 007 1029 5605 007 1030 42 MS 150 TC