Konica Minolta bizhub C3350 bizhub C3850/C3350 Maintenance/Troubleshooting Use - Page 55

Troubleshooting for paper jam, Tray 1, Manual Feed Tray, Tray 2/3, Symptom, Cause, Action

|

View all Konica Minolta bizhub C3350 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 55 highlights

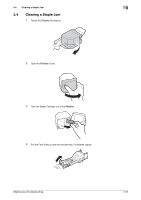

3.3 Troubleshooting for paper jam 3 Symptom A paper jam has occurred in the paper tray. Cause Paper is not loaded in the correct position in the paper tray. The number of sheets in the paper tray exceeds the maximum capacity. The width of the paper guide has not adjusted to the paper size. Bent or creased paper has been loaded into the paper tray. Paper is damp. Envelopes are loaded in Tray 2/3. Thick paper, label sheets, postcards, glossy paper, or letterheads are loaded in Tray 2/3. Label sheets are loaded in an incorrect orientation. Envelopes are loaded in an incorrect orientation. Invalid paper (paper of an invalid size, thickness, or type) is used. The Paper Feed Rollers are dirty. Action Remove the jammed paper, then correctly load paper into the paper tray. Remove excessive sheets in the paper tray, then re-load paper into the paper tray. Adjust the paper guide in the paper tray to the paper size. Remove the bent or creased paper, then load new paper into the paper tray. Remove damp paper, then load new dry paper into the paper tray. Load envelopes into Tray 1 or the Manual Feed Tray. Load thick paper, label sheets, postcards, glossy paper, or letterheads into Tray 1 or the Manual Feed Tray. Correct the orientation of label sheets. Place an envelope with the flap facing upward. When the flap is in the long side of an envelope, load it in the machine side. Use our recommended paper. For information on the available paper, refer to Chapter 6 "Loading Paper" in [User's Guide Introduction]. Clean the Paper Feed Rollers. For details, refer to page 1-5. Tips If a paper jam frequently occurs in a specific place, carry out checks, repairs, or cleaning focusing on the jam location. [Maintenance/Troubleshooting] 3-15