Lexmark 11C0200 Service Manual - Page 209

Lexmark 11C0200 - Optra SC 1275 Color Laser Printer Manual

|

UPC - 734646126885

View all Lexmark 11C0200 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 209 highlights

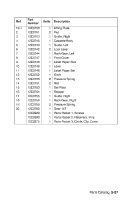

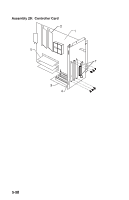

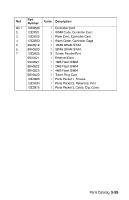

O oil coating roller removal 3-9 operator error message table 2-2 operator menu disabled 2-48 P paper exit removal 3-12 paper feed operation 1-2 paper jam service check 2-35 paper size/cassette detecting board removal 3-19 paper take-up removal 3-19 paper take-up 2 assembly 5-22 paper type detection 1-8 parallel wrap test 2-53 parts not to be touched 3-2 parts of the printer 4-1 power supply cooling fan motor service check 2-39 power unit frame removal 3-14 power unit removal 3-13 precautions for disassembly and cleaning 3-1 print tests 2-50 printed circuit boards 4-19 printhead cooling fan service check 2-39 printhead frame removal 3-15 printhead removal 3-11 printing process 4-6 service checks 2-33 service error message table 2-26 setting printer registration 2-50 setting the page count 2-58 shield plate removal 3-13 size sensing sensor test 2-55 start 2-1 status messages 2-2 suction assembly removal 3-25 suction fan motor removal 3-27 suction fan motor service check 2-39 supplies status messages 2-11 switches and sensors 4-7 symptom table 2-29 synchronizing rollers 1-7 T third cassette assembly 5-54 toner cartridge rack removal 3-16 toner cartridge rack service check 2-38 toner empty/toner cartridge board removal 3-16 toner empty/toner cartridge detection 1-10 tools 1-1 transfer belt assembly 5-24 transfer roller assembly 5-28 transport motor service check 2-34 Q quality pages 2-51 quick disk check 2-57 V viewing the error log 2-58 viewing the permanent page count 2-58 R rack lever solenoid adjustment 3-5 registration adjustment 3-3 removal procedures 3-5 ROM memory test 2-52 W waste toner bottle removal 3-7 S safety information viii second cassette assembly 5-50 sensor service check 2-47 X-2