Lexmark E450DN User's Guide - Page 18

Storing print media, Avoiding jams - remove print media

|

View all Lexmark E450DN manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 18 highlights

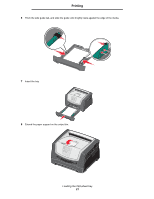

Understanding print media guidelines • Do not use preprinted card stock manufactured with chemicals that may contaminate the printer. Preprinting introduces semi-liquid and volatile components into the printer. • The use of grain short card stock is recommended. Storing print media Use the following guidelines to avoid paper feeding problems and uneven print quality. • For best results, store media in an environment where the temperature is approximately 21°C (70°F) and the relative humidity is 40%. Most label manufacturers recommend printing in a temperature range of 18 to 24°C (65 to 75°F) with a relative humidity of 40 to 60%. • Store cartons of media on a pallet or shelf, rather than directly on the floor. • When storing individual packages of media out of the original carton, make sure they rest on a flat surface so the edges do not buckle or curl. • Do not place anything on top of the media packages. • Store paper in its original wrapper until you load it into the printer. Avoiding jams Use appropriate print media (paper, transparencies, labels, and card stock) to help ensure trouble-free printing. See What types of print media can be loaded? on page 12 for more information. Note: Try a limited sample of any print media you are considering using with the printer before purchasing large quantities. By selecting the appropriate print media and loading it properly, you can avoid most jams. For detailed tray loading instructions, see the following: • Loading the 250-sheet tray on page 19 • Loading the manual feeder on page 23 The following hints can help you avoid jams: • Use only recommended print media. • Do not overload the print media sources. Make sure the stack height does not exceed the maximum height indicated by the stack line on the labels in the sources. • Do not load wrinkled, creased, damp, or curled print media. • Flex, fan, and straighten print media before you load it. If jams do occur with print media, try feeding one sheet at a time through the manual feeder. • Do not use print media that you have cut or trimmed yourself. • Do not mix print media sizes, weights, or types in the same print media source. • Make sure the recommended print side is loaded in the source according to your simplex or duplex needs. • Keep print media stored in an acceptable environment. See Storing print media on page 18. • Do not remove trays during a print job. • Push all trays in firmly after loading them. • Make sure the guides in the trays are properly positioned for the size of print media you have loaded. Make sure the guides are not placed too tightly against the stack of print media. Storing print media 18