Samsung SCX 6322DN Service Manual - Page 100

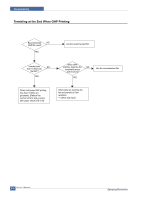

Check CBF Harness_CN7.Main PBA to LSU

|

UPC - 635753620658

View all Samsung SCX 6322DN manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 100 highlights

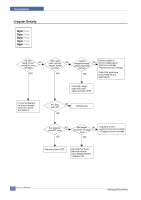

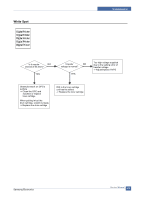

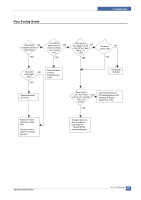

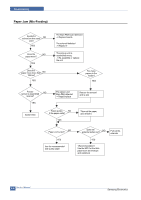

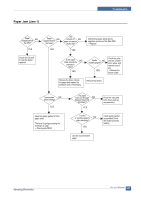

Troubleshooting Error Status Jam 2 Check Check where Jam 2 happens 1. Paper is curled and cannot exit. 2. Paper is curled in the exit cover?. Jam 2 at face-down tray 1. Then paper is not drawn in because of the stack of papers in the Out tray. 2. Does it curl while coming out? Clutch error High voltage error 1. Check the spring of solenoid 2. Check the armature assembly/cushion 3. Electrical check 1. Check the terminal output voltage Feeding obstacles 2. Check HVPS Does the Plate-knockup prevent the paper loading? Solution 1. Remove paper using pinset or some tool and watch if separate claws have any troble. Clean around fuser. 2. Check locking works wells. Watch whether the ribs of exit cover hace any burr or resisitive edge. If they do, remove obstacles or replace. 1. Load recommended quantity of papers 2. Open the Cover Front and check whether roller or spring, which are related to paper out, is not out of position. If so, re-locate or replace. 1. Check whether the spring is expanded or not. 2. Check armature is well installed. It may be unstable assemble. 3. Remove the Main PBA. 1. Remove the Toner cartridge and open the cover and press cover open switch lever and measure the voltage with high voltage probe and sending printing data. If the voltage is normal, change the toner cartridge. 2. Disassemble the left side cover, and check HV of the solder side of HVPS and change it. MPF : Turn the power off and on. Open and close the Side cover to return to the original state. Skew Stacking Engine Error Document Jam Is the Guide adjust set to the paper width? 1. Took out the Stacker extender to support long papers? 2. Stacked too many papers more than Stacker can hold? Check CBF Harness_CN7.(Main PBA to LSU) Document is not picked up(in ADF). Document is stopped after it has fed into the ADF. Does it curl while coming out? Cassette : Adjust Guide to fit the paper width. Fit the paper width using the Guide adjust. 1. Use extender as per the paper length. 2. The Face-up stacker normally can hold 100 pages when using 75g/m2, however, stacking capacity can be lowered depending on the type of papers. Refer to troubleshooring "ENGINE ERROR". 1. Check document is well stocked in ADF. 2. Check whether document was been fastened together by staple or clip. 3. Load recommended quantity of papers. 1. Check whether the Reg. sensor is working or not. 2. Check whether the Feed Roller is working or not. 1. Check the Open Cover whether there are bosses. 2. Check the ADF ass'y is well assemble. Samsung Electronics Service Manual 6-23