Samsung SCX 6322DN Service Manual - Page 99

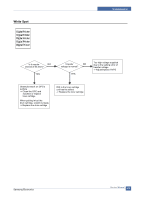

Malfunction - open heat error

|

UPC - 635753620658

View all Samsung SCX 6322DN manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 99 highlights

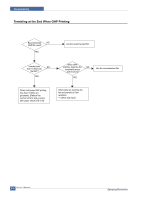

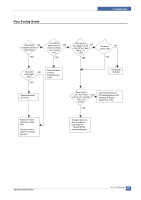

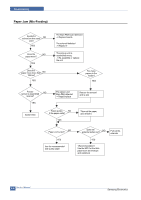

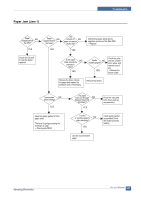

Troubleshooting 6.2.4 Malfunction Error Status No power Fuser Error Cover open Jam 0 Jam 1 Check 1. Check power is supplying 2. Check fuse F1 open 1. Thermostat open 2. AC wire open 3. Thermistor wire open 4. Main PBA 1. When close Side cover, check the lever is pressed 2. Micro switch's contact 3. CPU and related circuit Solution 1. If supplying power differs from machine's power rating, replace the machine. 2. Replace it. 1. Detach AC connector and measure the resistane between pin 1 and 2. If it is megohm, thermostat is open, Replace it. 2. Check bad connector contact or wire is cut. 3. Check thermistor wire and its connection. 4. Replace Main PBA 1. Open Side cover and press the lever with pen. If Controller detects cover close, there is some mechanical trouble in Side cover and lever's assembly. If not so there is electrical problem. Check where Jam 0 happens 1. Paper is not picked up 2. Paper is located in feed sensor 3. Happened when inserting specific papers such as envelope into the MPF (Multipurpose Paper Feeder)? 4. Happened when inserting specific papers such as envelope into the Manual Feeder? 5. Is the Stacker Extender is folded out? 6. Does not the Guide Adjust distort the papers Paper is stopped in just after of fuser unit. 1. Check whether solenoid is working or not by using Engine test mode 2. Check feed sensor malfunction. 3. Re-try inserting a fewer papers. •fan the papers and align •take out the loaded papers and insert them reverse direction 4. Take out the loaded papers and insert them reverse direction •inserted papers as recommended for Manual Feeding? •When loading, tap the papers until paper detect sensor senses loading 5. When using long papers, use the Stacker Extender 6. Adjust Guide to fit the paper width 1. It is mostly resulted from double feeding. Check paper is well stocked in feeder. 2. Check feed actuator position and actuator's operating. There may be stiff movind or double reflection. If not so, check the operation of feed sensor by Engine test mode. 3. Check exit lever operation. Remore jam and check actuator moving by hand. If actuator is too stiff, paper is wrapped around the heat roller. Remove obstacles or replace. 6-22 Service Manual Samsung Electronics