Samsung SCX 6322DN Service Manual - Page 51

Abnormal Image Printing and Defective Roller

|

UPC - 635753620658

View all Samsung SCX 6322DN manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 51 highlights

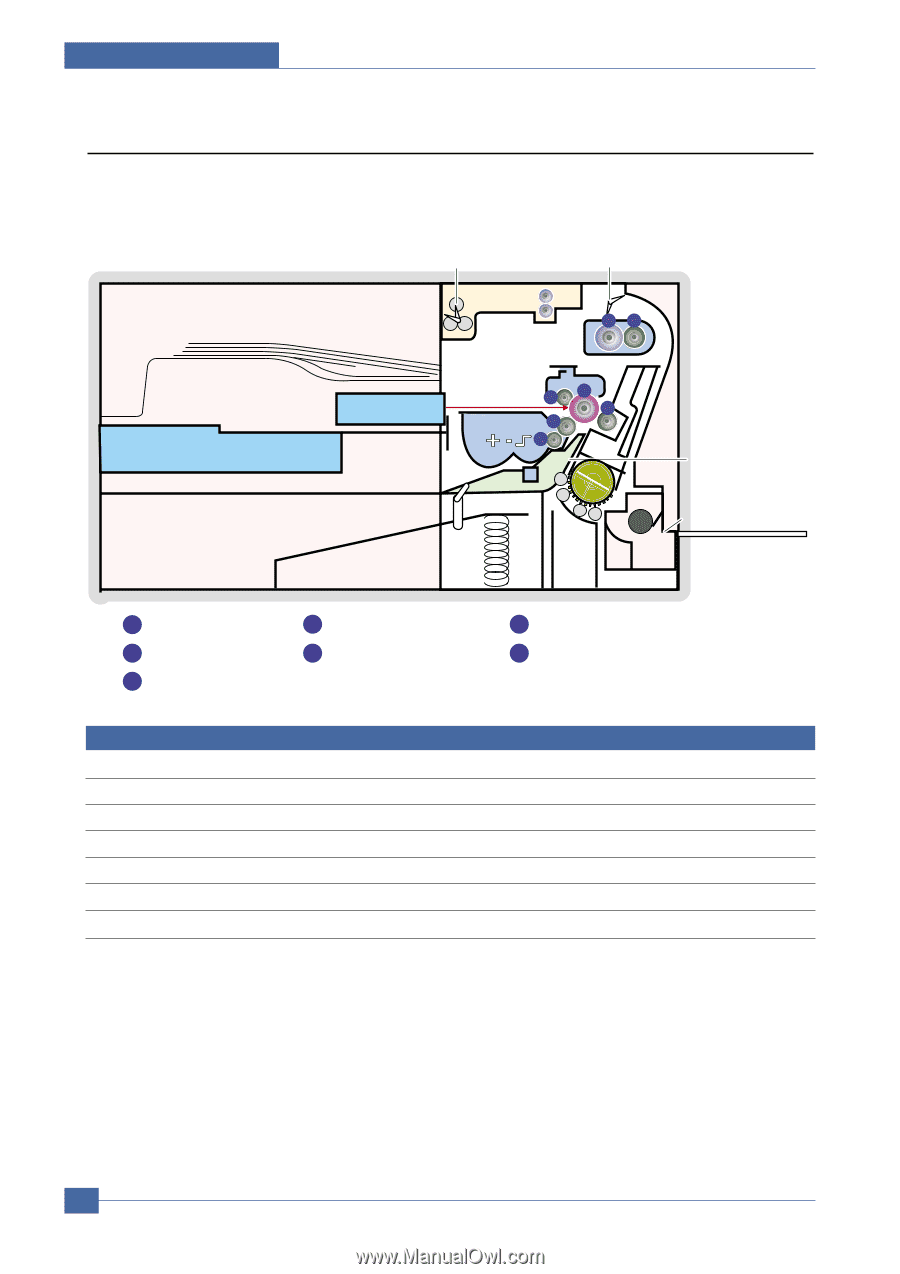

Alignment & Adjustments 4.6 Abnormal Image Printing and Defective Roller If a mark or other printing defect occurs at regular intervals down the page it may be caused by a damaged or contaminated roller. Measure the repetition interval and refer to the table below to identify the roller concerned. Main Board+Engine Board SMPS EBXINITFUSELNLSSOERNSOR EXIT SENSOR EXIT UNIT OPCFUSNEITR 67 LIU OPC UNIT 2 TONER UNIT 4 3 1 5 OPC DRUM TR FTL EMPTY SEN PICKUP ROLL FEEDER FEED SENSOR EMPTY SENSOR(MPF) MPF 1 OPC Drum 2 Charge Roller 3 Supply Roller 4 Developing Roller 5 Transfer Roller 6 Heat Roller 7 Pressure Roller No Roller Abnormal image period Kind of abnormal image 1 OPC Drum 94.30mm White spot, Block spot 2 Charge Roller 38.30mm Black spot 3 Supply Roller 43.80mm Horizontal density band 4 Develop Roller 54.30mm Horizontal density band 5 Transfer Roller 56.60mm Black side contamination/transfer fault 6 Heat Roller 83.60mm Black spot and fuser ghost 7 Pressure Roller 91.00mm Black side contamination 4-24 Service Manual Samsung Electronics