Craftsman 28913 Operation Manual - Page 26

<4::7

|

View all Craftsman 28913 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 26 highlights

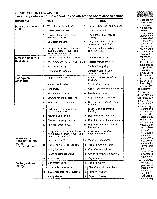

2. Check that holes '7_' in governor control lever and hole in governor plate line- up. if holes '_' are not aligned, loosen clamp screw and move throttle cable until holes are aligned. Tighten clamp screw securely. Governor Control Lever Governor Control Plate

2.

Check

that

holes

'7_' in governor

control

lever

and

hole

in

governor

plate

line-

up.

if holes

'_'

are not aligned,

loosen

clamp

screw

and move throttle

cable until

holes

are aligned.

Tighten

clamp

screw

securely.

Governor Control Lever

Governor

Control

Plate

<4::7

o

Holes '_' _:.

_hrottle

[

_.,

Clamp

UU1L_j)

_M_,

"-- 1_]

Screw

_

.....

TO

ADJUST

CARBURETOR

NOTE:

The

carburetor

on this

engine

is

low

emissiom

It is equipped

with

an

idle

fuel

adjusting

needle

with

a

limiter

cap,

which

allows

some

adjustment

within

the

limits

allowed

by the

cap.

Do

not attempt

to

remove

the limiter

cap.

The

limiter

cap

cannot

be

removed

without

breaking

the

adjusting

needle.

The

carburetor

has

been

preset

at the fac-

tory

and

adjustment

should

not

be neces-

sary.

However,

minor

adjustment

may

be

required

to

compensate

for

differences

in

fuel,

temperature,

altitude

or

load.

If the

carburetor

does

need

adjustment,

proceed

as follows:

In

general,

turning

idle

mixture

valve

in

(clockwise)

decreases

the supply

of fuel

to

the

engine

giving

a leaner

fuel/air

mixture.

Turning

the idle mixture

valve

out

(counter-

clockwise)

increases

the supply

offuel

to the

engine

giving

a richer

fuel/air

mixture.

IMPORTANT:

Damage

to the needle

valve

and the seat in carburetor

may result

if screw

is turned

in too tight.

PRELIMINARY

SETTING

-

1.

Air cleaner

assembly

must be assembled

to the carburetor

when

making

carburetor

adjustment&

2,

Be sure

the throttle

control

cable

is ad-

justed

properly

(see

above).

FINAL

SETTING

-

1.

Start

engine

and

allow

to warm

for

five

minutes.

Make

final

adjustments

with

engine

running

and

shift/motion

control

lever

in neutral

(N)

position,

2.

Move

throttle

control

lever

to slow

posi-

tion.

With

finger,

rotate

and

hold throttle

lever

against

idle speed

screw.

lParn idle

speed

screw

to attain

1750

RPM.

3_ While

still

holding

throttle

lever

against

idle

speed

screw,

turn

idle

mixture

valve

full

travel

clockwise

then

counter-

clockwise

until

engine

runs

rough

Turn

valve

to

a point

midway

between

those

two positions.

Release

throttle

lever,

ACCELERATION

TEST

4,

Move

throttle

control

lever

from

slow

to fast

position.

If engine

hesitates

or

dies,

turn

idle

mixture

valve

out

(coun-

terclockwise)

1/8 turn.

Repeat

test

and

continue

to

adjust,

if

necessary,

until

engine

accelerates

smoothly.

High

speed

stop is factory

adjusted.

Do not

adjust

- damage

may

resulL

IMPORTANT:

Never

tamperwith

the engine

governor,

which

is

factory

set

for

proper

engine

speed.

Overspeeding

the

engine

above

the factory

high speed

setting

can be

dangerous_

Ifyou thinkthe

engine-governed

high speed

needs

adjusting,

contact

a Sears

or other

qualified

service

center,

which

has

proper

equipment

and

experience

to

make

any necessary

adjustments.

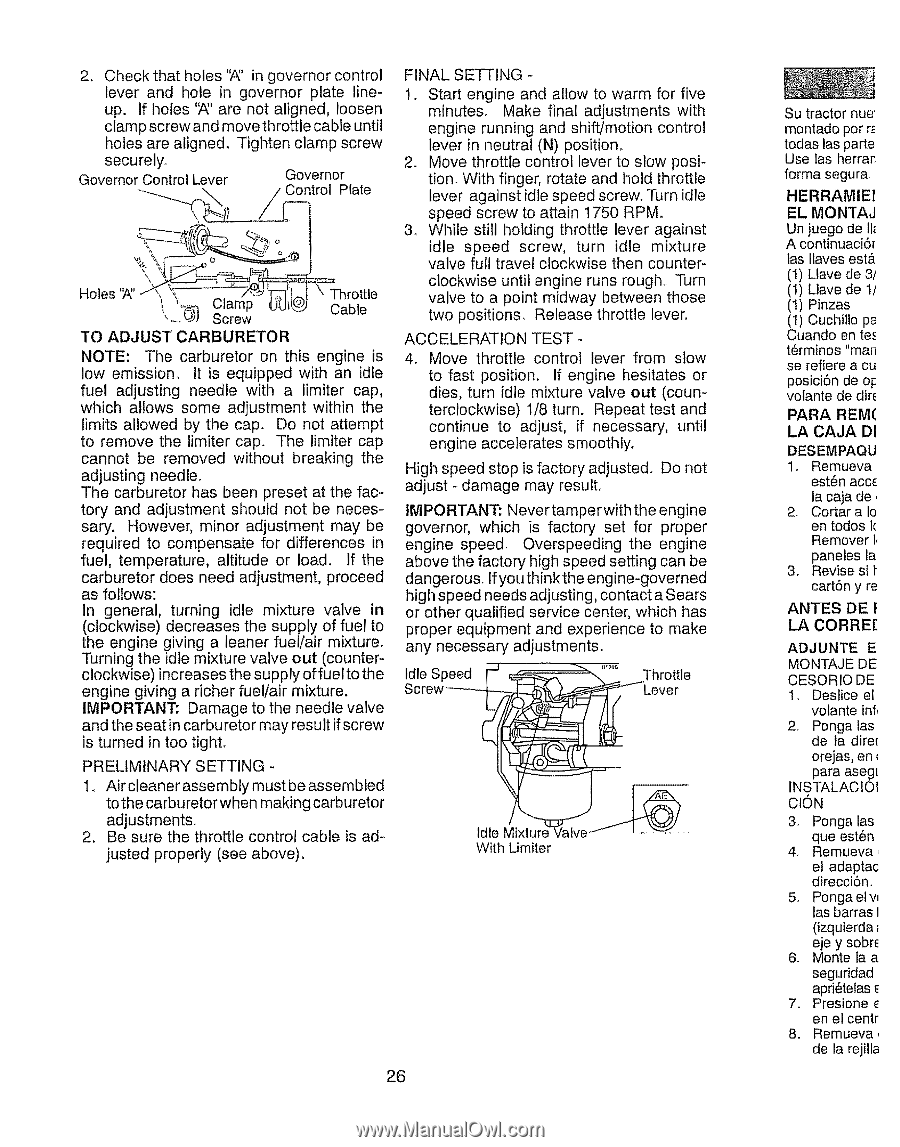

Idle Speed

F

_f_--_"-_"""

Throttle

Screw--_

'Lever

C

Idle Mixture Valve

/

_

With Umiter

26

Su tractor nue'

montado por r_

todas las parte

Use las herran

forma segura,

HI=RRAMIEI

E1 MONTAJ

Un juego de i1_

A continuaci6r

tas llaves est&

(1) Llave de 3/

(1) Llave de t/

(!)

Pinzas

(I)

Cuchi]lo pa

Cuando en tee

t6rminos

"man

se

refiere

a cu

posici6n de oi:

volante de dire

PARA

REM(

LA CAJA

DI

DESEMPAQU

1o Remueva

est6n accE

la caja de,

2,

Cortar a Io

en todos k

Remover

I,

paneles la

3.

Revise si i"

cart6n y re

ANTES

DE

!

LA

CORREr

ADJUNTE

E

MONTAJE DE

CESORIO DE

1.

Deslice el

votante inf,

2.

Ponga fas

de la dire[

orejas, en

para asegl

INSTALACIOI

OlON

3_

Ponga las

que est6n

4o

Remueva

el adaptac

direcci6no

5.

Pongaelw

las barras I

(izquierda

eje y sobr_

6.

Monte la a

seguridad

apri_telas E

7.

Presione

en el centr

8.

Remueva,

de la rejilla