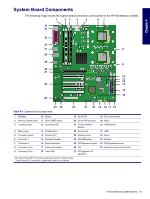

HP Xw6200 HP Workstation xw6200 Service and Technical Reference Guide (3rd Edi - Page 66

Recommended Materials and Equipment, Tools and Software Requirements, Screws

|

UPC - 882780333536

View all HP Xw6200 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 66 highlights

„ Handle electrostatic sensitive components, parts, and assemblies by the case or PCB laminate. Handle them only at static-free work areas. „ Turn off power and input signals before inserting and removing connectors or test equipment. „ Use fixtures made of static-safe materials when fixtures must directly contact dissipative surfaces. „ Keep work area free of nonconductive materials, such as ordinary plastic assembly aids and Styrofoam. „ Use field service tools, such as cutters, screwdrivers, and vacuums, that are conductive. Recommended Materials and Equipment Materials and equipment that are recommended for use in preventing static electricity include: „ Antistatic tape „ Antistatic smocks, aprons, or sleeve protectors „ Conductive bins and other assembly or soldering aids „ Conductive foam „ Conductive tabletop workstations with ground cord of one-megohm ± 10% resistance „ Static-dissipative table or floor mats with hard tie to ground „ Field service kits „ Static awareness labels „ Wrist straps and footwear straps providing one-megohm ± 10% resistance „ Material handling packages „ Conductive plastic bags „ Conductive plastic tubes „ Conductive tote boxes „ Opaque shielding bags „ Transparent metallized shielding bags „ Transparent shielding tubes Tools and Software Requirements „ Torx T-15 screwdriver or Flat-bladed screwdriver (can be used in place of the Torx screwdriver) „ Diagnostics software Screws The screws used in the workstation are not interchangeable. They might have standard or metric threads and might be of different lengths. If an incorrect screw is used during the reassembly process, it can damage the unit. HP strongly recommends that all screws removed during disassembly be kept with the removed part, then returned to their proper locations. 66 REMOVAL AND REPLACEMENT PROCEDURES