LiftMaster LA400DC LA400DC Owner's Manual - Page 11

Installation, Important Safety Information

|

View all LiftMaster LA400DC manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 11 highlights

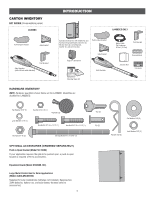

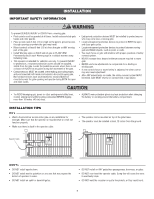

INSTALLATION IMPORTANT SAFETY INFORMATION To prevent SERIOUS INJURY or DEATH from a moving gate: • Pinch points must be guarded at all times. Install enclosed-style gate tracks and roller guards. • Place screen mesh 6 feet (1.8 m) high on the gate to prevent access through openings anywhere the gate may travel. • Mount controls at least 6 feet (1.8 m) from the gate or ANY moving part of the gate. • Install Warning signs on EACH side of gate in PLAIN VIEW. Permanently secure each Warning sign in a suitable manner using fastening holes. • This operator is intended for vehicular use only. To prevent INJURY to pedestrians, a separate pedestrian access should be supplied, visible from the gate. Locate the pedestrian access where there is not a chance of INJURY at any point during full movement of the gate. • Contact sensors MUST be located at the leading and trailing edges, and post mounted both inside and outside a horizontal swing gate. Non-contact sensors such as photoelectric sensors MUST be mounted across the gate opening and operate during BOTH the open and close cycles. • Entrapment protection devices MUST be installed to protect anyone who may come near a moving gate. • Locate entrapment protection devices to protect in BOTH the open and close gate cycles. • Locate entrapment protection devices to protect between moving gate and RIGID objects, such as posts or walls. • Too much force on gate will interfere with proper operation of safety reversal system. • NEVER increase force beyond minimum amount required to move gate. • NEVER use force adjustments to compensate for a binding or sticking gate. • If one control (force or travel limits) is adjusted, the other control may also need adjustment. • After ANY adjustments are made, the safety reversal system MUST be tested. Gate MUST reverse on contact with a rigid object. • To AVOID damaging gas, power or other underground utility lines, contact underground utility locating companies BEFORE digging more than 18 inches (46 cm) deep. • ALWAYS wear protective gloves and eye protection when changing the battery or working around the battery compartment. INSTALLATION TIPS DO's • Weld a horizontal bar across entire gate on any installation for strength. Make sure that the operator is mounted level or it will not function properly. • Make sure there is slack in the operator cable. • The operator can be mounted on top of the gate frame. • The operator must be installed at least 12 inches from the ground. Operator Cable DON'Ts • DO NOT install upside down. • DO NOT install next to sprinklers or any area that may expose the bottom of operator to water. • DO NOT install on uphill or downhill gates. • DO NOT install on ANY pedestrian passageways, doorways, or gates. • DO NOT over-bend the operator cable. Doing this will cause the wires to eventually break. • DO NOT weld the crossbar on just a few pickets, or they could bend. 9