LiftMaster LA400DC LA400DC Owner's Manual - Page 37

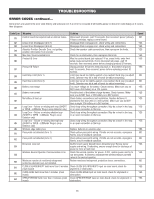

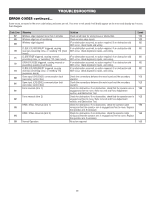

Code Error, Meaning, Solution, Saved, or OPEN - LiftMaster Plug-in Loop Detector only

|

View all LiftMaster LA400DC manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 37 highlights

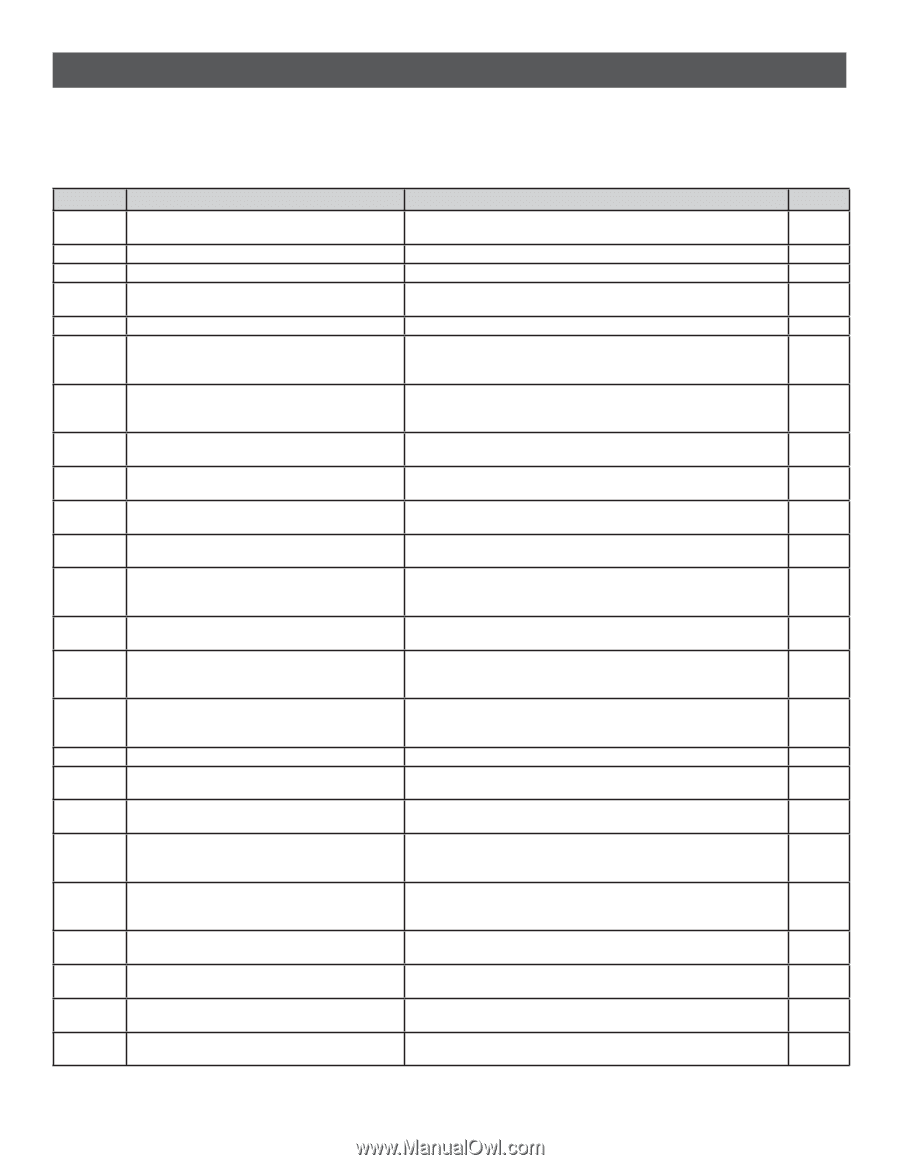

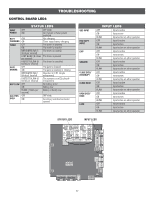

TROUBLESHOOTING ERROR CODES continued... Some errors are saved in the error code history and some are not. If an error is not saved it will briefly appear on the error code display as it occurs, then disappear. Code Error 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 51 52 53 54 60 61 62 63 Meaning Solution Control board has experienced an internal failure. Disconnect all power, wait 15 seconds, then reconnect power (reboot). If issue continues, replace control board. Linear Drive Disengaged (Arm 1) Disengage then re-engage arm, check wiring and connections. Linear Drive Disengaged (Arm 2) Disengage then re-engage arm, check wiring and connections. Absolute Position Encoder Error, not getting position information from encoder Check the operator cable connections, then reprogram the limits. Max-Run-Time Exceeded Error Check for an obstruction, then reprogram the limits. Product ID Error Was the control board just replaced? If so, erase limits, enter limit setup mode and set limits. If not, disconnect all power, wait 15 seconds, then reconnect power before changing product ID harness. Product ID Failure Unplug product ID harness then plug back in. Disconnect all power, wait 15 seconds, then reconnect power before replacing product ID harness. Hard Stop Limit (Arm 1) Limit may be set too tightly against a non-resilient hard stop (re-adjust limit). Operator may be at end of travel (re-adjust mounting). Hard Stop Limit (Arm 2) Limit may be set too tightly against a non-resilient hard stop (re-adjust limit). Operator may be at end of travel (re-adjust mounting). Battery overvoltage Too much voltage on the battery. Check harness. Make sure you do NOT have a 24V battery on a 12V system. Battery overcurrent Possible short of the battery charge harness. Check harness. Make sure you do NOT have a 12V battery on a 24V system. No battery at boot up Check battery connections and installation. Replace batteries if depleted to less than 20V on a 24V system. Make sure you do NOT have a single 12V battery on a 24V system. Loop Error - Failure or missing exit loop (SHORT Check loop wiring throughout connection. May be a short in the loop, or OPEN - LiftMaster Plug-in Loop Detector only) or an open connection in the loop. Loop Error - Failure or missing shadow loop (SHORT or OPEN - LiftMaster Plug-in Loop Detector only) Check loop wiring throughout connection. May be a short in the loop, or an open connection in the loop. Loop Error - Failure or missing interrupt loop (SHORT or OPEN - LiftMaster Plug-in Loop Detector only) Check loop wiring throughout connection. May be a short in the loop, or an open connection in the loop. Wireless edge battery low Replace batteries in wireless edge. Pass-point not detected (Arm 1) Check yellow pass-point wiring. If limits are not accurate, reprogram. Rarely, may be standard operation. Pass-point not detected (Arm 2) Check yellow pass-point wiring. If limits are not accurate, reprogram. Rarely, may be standard operation. Brownout occurred AC/DC board supply dipped below allowable level. Review power supply and wiring. If rebooting, ensure enough time for discharge of power to force a fresh boot. Wireless Second Operator Communication Error Check the second operator for power. If OFF, restore power and try to run the system. If powered, deactivate the wireless feature and then re-learn the second operator. Minimum number of monitored entrapment protection devices (one) not installed. Review monitored entrapment protection device connections. CLOSE EYE/INTERRUPT held more than 3 minutes Check CLOSE EYE/INTERRUPT input on main board; check for (main board) alignment or obstruction. CLOSE EDGE held more than 3 minutes (main board) Check CLOSE EDGE input on main board; check for alignment or obstruction. OPEN EYE/EDGE held more than 3 minutes (main Check OPEN EYE/EDGE input on main board; check for alignment or board) obstruction. Saved NO YES YES YES YES YES YES NO NO YES YES YES YES YES YES YES NO NO YES YES NO YES YES YES 35