LiftMaster LA400DC LA400DC Owner's Manual - Page 40

Troubleshooting Chart, Symptom, Possible Causes, Solutions

|

View all LiftMaster LA400DC manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 40 highlights

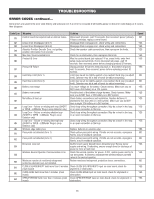

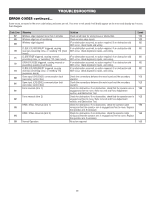

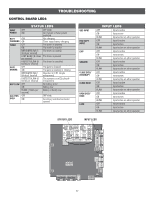

TROUBLESHOOTING TROUBLESHOOTING CHART SYMPTOM POSSIBLE CAUSES SOLUTIONS Operator does not a) No power to control board a) Check AC and battery power run and error code b) Open fuse b) Check fuses display not on. c) If on battery power only, low or dead batteries c) Charge batteries by AC or solar power or replace batteries d) Defective control board d) Replace defective control board Control board powers up, but motor does not run. a) Reset button is stuck b) Stop button active or jumper not in place for stop circuit c) If on battery power only, low or dead batteries a) Check Reset button b) Check Stop button is not "stuck on", or verify that the stop button is a normally closed circuit, or put a jumper on the stop circuit. c) Charges batteries by AC or solar power or replace batteries d) Open or Close input active d) Check all Open and Close inputs for a "stuck on" input e) Entrapment Protection Device active e) Check all Entrapment Protection Device inputs for a "stuck on" sensor f) Vehicle loop detector or probe active f) Check all vehicle detector inputs for a "stuck on" detector g) Defective control board g) Replace defective control board Arm moves, but cannot set correct limits. a) Arm does not extend or retract enough during travel b) Arm is interfering with mounting bracket c) Gate is too difficult to move a) Disengage the arm and ensure arm moves freely b) Examine the hinge point where the arm mounts to the gate post. Make sure that the arm housing does not hit or interfere with the gate post or mounting bracket. Correct as necessary. c) Disconnect arm from gate and move gate manually. Gate must move easily and freely through its entire range, limit-to-limit. Repair gate as needed. Gate does not fully open or fully close when setting limits. a) Arm does not extend or retract enough during travel b) Arm is interfering with mounting bracket c) Gate is too difficult to move a) Disengage the arm and ensure arm moves freely b) Examine the hinge point where the arm mounts to the gate post. Make sure that the arm housing does not hit or interfere with the gate post or mounting bracket. Correct as necessary. c) Remove arm from gate and move gate manually. Gate must move easily and freely through its entire range, limit-to-limit. Repair gate as needed. Operator does not respond to a wired control/command (example: Open, Close, SBC, etc.) a) Check Open and Close command input LEDs b) Stop button is active c) Reset button is stuck d) If on battery power only, low or dead batteries a) Check all Open and Close inputs for a "stuck on" input b) Check Stop button is not "stuck on" c) Check Reset button d) Charges batteries by AC or solar power or replace batteries e) Entrapment Protection Device active e) Check all Entrapment Protection Device inputs for a "stuck on" sensor f) Vehicle loop detector or vehicle probe active f) Check all vehicle detector inputs for a "stuck on" detector Operator does not respond to a wireless control or transmitter a) Check XMITTER LED when wireless control is active b) Stop button is active c) Reset button is stuck a) Activate wireless control and check XMITTER LED is on. Re-learn wireless control/transmitter to control board. Replace wireless control as needed. b) Check Stop button is not "stuck on" c) Check Reset button d) Poor radio reception d) Check if similar wired control operates correctly. Check if wireless controls works properly when within a few feet of operator. Check operator's antenna and antenna wire. Check other wireless controls or devices. Gate stops during a) Control (Open, Close) becoming active travel and reverses b) Vehicle loop detector active immediately. c) Low battery voltage a) Check all Open and Close inputs for an active input b) Check all vehicle detector inputs for an active detector c) Battery voltage must be 23.0 Vdc or higher. Charge batteries by AC or solar power or replace batteries Gate opens, but will not close with transmitter or Timer-to-Close. a) Open control active b) Vehicle loop detector active c) Loss of AC power with AC FAIL set to OPEN d) Low battery with LOW BATT set to OPEN e Fire Dept input active f) Timer-to-Close not set g) Close Entrapment Protection Device active a) Check all Open inputs for an active input b) Check all vehicle detector inputs for an active detector c) Check AC power and AC Fail option setting d) Check if AC power is available. If no AC power, then running on batteries and battery voltage must be 23.0 Vdc or higher. Charge batteries by AC or solar power or replace batteries. e) Check Fire Dept input f) Check Timer-to-Close (TTC) setting g) Check all Entrapment Protection Device inputs for an active sensor 38