Maytag MAH5500BWW Service Manual - Page 37

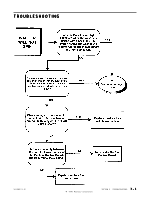

Ticking or Knocking Noise In Spin - bearing

|

View all Maytag MAH5500BWW manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 37 highlights

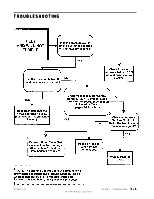

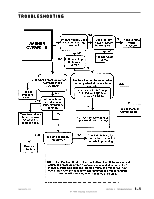

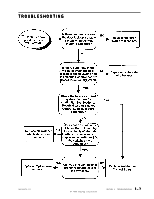

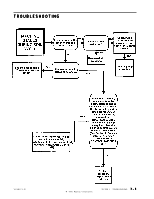

Door Leaks: Dispenser Does Not Dispense: Usually this occurs when the door is remounted into the shroud and the technician fully tightens the top hinge screw prior to inserting the lower screw. The technician should fully seat the door into the shroud evenly prior to tightening the hinge bracket screw into the shroud. Check also for excess plastic flashing in the tab area of the plastic shroud. Carefully remove the excess flash and remount the boot gasket. "Thumping" Noise In Spin: The noise could be from loose lower front weight mounting bolts or a loose bolt securing the driven pulley. Check the belt for a weak seam and replace if necessary. Check the motor adjustment bolt for tightness. "Ticking or Knocking" Noise In Spin: The noise could be from a loose wire harness, plastic purse-lock wire harness retainer on upper hose hitting the topcover or a plastic injection mold standoff on the outer tub bearing housing may possibly be interfering with the driven pulley. Examine the siphon cap to see if the cap was twisted, causing the cap to seal the siphon tube against the bottom of the siphon cup. Reposition cap to lift the siphon tube off the bottom of the cup. The wax motors are activated a full 30 seconds prior to turning on the water valves. If the timing is not correct, suspect a bad wiring connection. Also, examine the linkage of the acutuator arm and proper location of the spring on the wax motor (See Section 6: Water Carrying Components). Clothes Wet: Possibly due to the washer shutting down too soon or execessive suds present. Did the timer advance to OFF? If yes, then excessive suds may be the cause or the intertial unbalance switch tripped too soon, resulting in lower spin speeds. Change the inertial switch if suds were not detected. Note: If the timer motor is energized for five minutes without the cycle inputs changing, the machine control board will drop the line voltage relay. Also, check the drive belt for a weak spot on the belt. Ussually felt on the backside of the belt as a "flat" spot. Replace the belt. RF (Radio Frequency) Interference: The interference could occur if the RPT shutter on the motor was misaligned or a motor terminal has been pushed inward slightly when the motor harness connector was placed on the motor. Remove the motor phase harness connector and check the motor terminals. Replace the motor if the motor teminals are loose. 16008373-01 © 1998 Maytag Corporation SECTION 3. TROUBLESHOOTING 3 - 3