Motorola V186 User Manual - Page 7

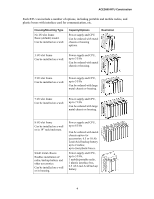

ACE3600 RTU Construction, Plastic slots which accommodate the power supply, CPU and I/O modules, - battery

|

View all Motorola V186 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 7 highlights

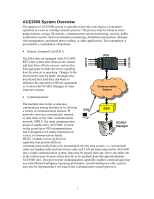

ACE3600 RTU Construction The ACE3600 RTU is a universal device that may serve as an RTU, a Programmable Logic Controller (PLC), or as the system FEP. It is placed at the system's field sites to collect data from on-site sensors, add data from off-site sources, and use this data aggregate to make decisions regarding how some process is operating. The RTU may make changes to the local process; messages may be initiated that send data elsewhere to influence the operation of off-site equipment or to advise the SCADA Manager of some important change. The ACE3600 is available in various structures: ƒ Frame which can accommodate a varied number and type of modules ƒ Metal chassis which accommodates the frame, and optional radios, backup battery and communication interfaces ƒ Protective housing which accommodates the frame, and optional radios, backup battery and communication interfaces (suitable for outdoor installation) The ACE3600 frame consists of the following elements: ƒ Plastic slots which accommodate the power supply, CPU and I/O modules, and backplane bus motherboard ƒ Mounting plate for attaching the plastic slots together and mounting the frame on a wall ƒ Backplane bus motherboard which connects the modules to each other via the signal buses and connects the modules with operating voltages ƒ Power junction box for AC or DC power source and ground connections A frame can be mounted on the wall or installed in a 19" rack or customer enclosure. 3