Ridgid MS255SR Operation Manual - Page 34

Troubleshooting - fuse

|

View all Ridgid MS255SR manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 34 highlights

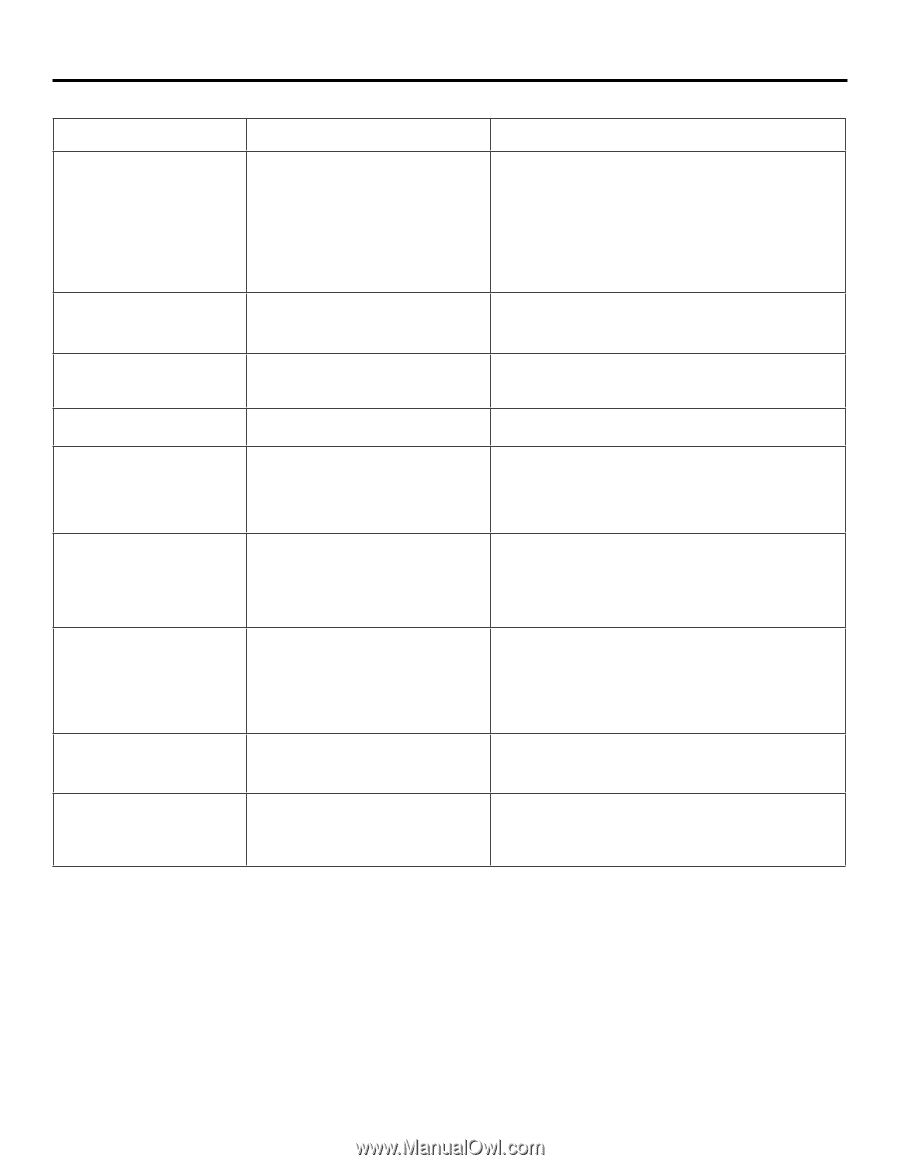

troubleshooting PROBLEM CAUSE SUGGESTED CORRECTIVE ACTION Brake does not stop blade 1. Motor brushes not seated or within 5 seconds. lightly sticking. 2. Motor brake overheated from use of defective or wrong size blade or rapid On/Off cycling. 3. Arbor bolt is loose. Motor does not start. 1. Fuse problem. 2. Brush worn. 1. Inspect/clean/replace brushes. See MAINTENANCE section. 2. Use a recommended blade. 3. Retighten. 1. Check time delay fuse or circuit breaker. 2. Replace brushes. See MAINTENANCE section. Brush sparks excessively 1. Brush worn/damaged. when switch is released. 1. Replace brushes. See MAINTENANCE section. Blade hits table. 1. Misalignment. 1. See ADJUSTMENT section. Angle of cut is inaccurate. 1. Miter table is unlocked. 1. Use miter-lock lever. See ADJUSTMENT section. 2. Too much sawdust under table. 2. Vacuum or blow out dust. WEAR EYE PROTECTION! Cutting arm cannot fully raise or blade guard cannot fully close. Blade binds, jams, or burns wood. 1. Parts failure. 2. Pivot spring not replaced properly after service. 3. Sawdust buildup. 1. Improper operation. 2. Dull blade. 3. Improper blade. 4. Warped blade. 1. Contact authorized service center. 2. Contact authorized service center. 3. Clean and lubricate moving parts. 1. See OPERATION section. 2. Replace or sharpen blade. 3. Replace blade. 4. Replace blade. Saw vibrates or shakes. 1. Saw blade is damaged. 1. Replace blade. 2. Saw blade is loosened. 2. Tighten arbor bolt. Laser line projection is hard to see. 1. Light in work area is too bright. 1. Move the Miter Saw to the work area with proper light. 2. Sawdust on the laser lens. 2. Clean laser lens with a soft, dry brush. 33