Sharp MX-M363N Installation Manual - Page 109

C. RSPF parallelism adjustment, and the RSPF glass height adjustment resin surface a,

|

View all Sharp MX-M363N manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 109 highlights

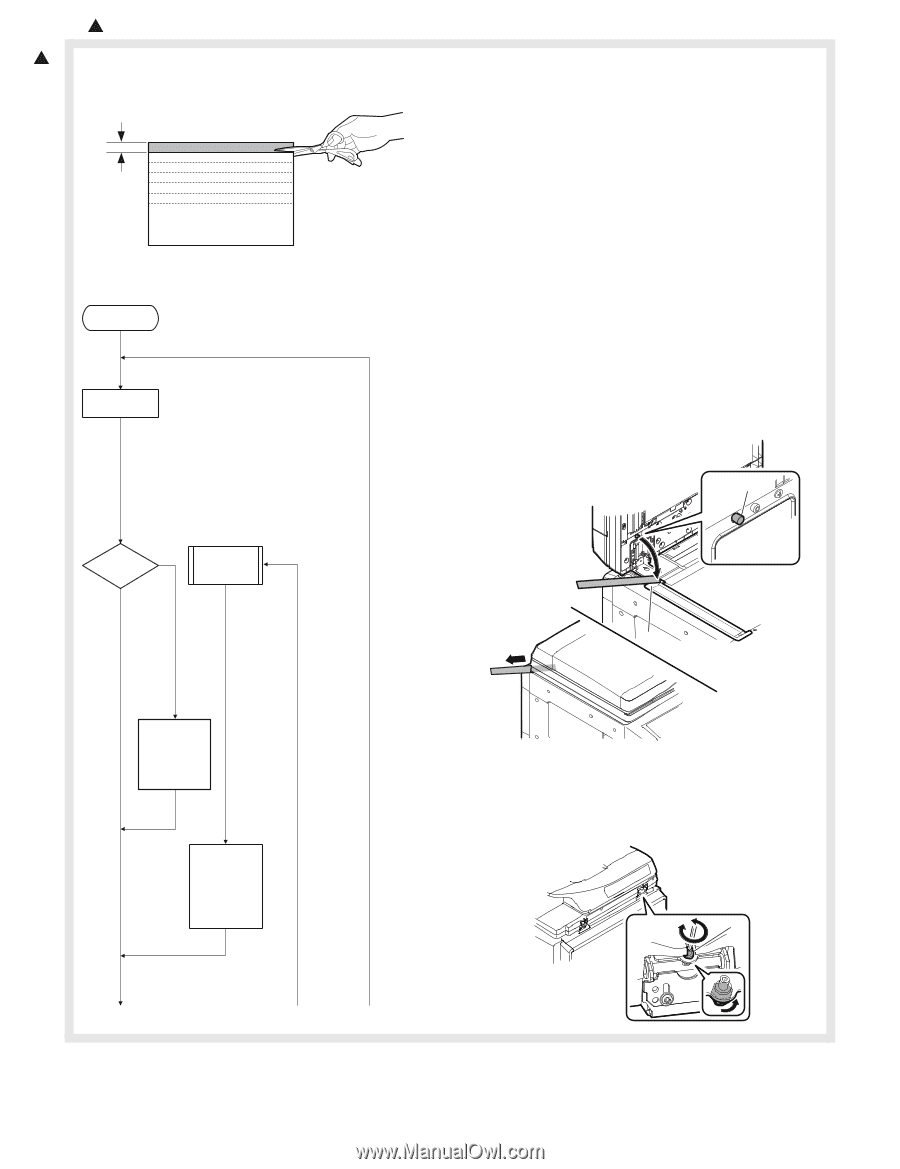

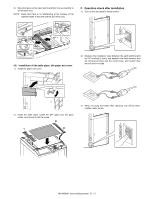

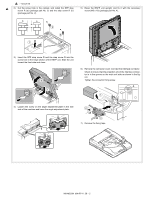

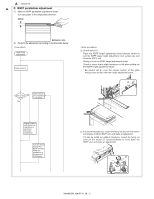

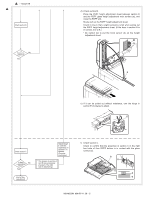

1 : '10/Jun/18 1 C. RSPF parallelism adjustment 1) Make an RSPF parallelism adjustment sheet. Cut copy paper in the longitudinal direction. 20mm A4/Letter size 2) Perform the adjustment according to the flowchart below. Start of the adjustment Check section A. Is there a resist- No ance? Yes The section A is lowered too much. a) Check section A. Place the RSPF height adjustment sheet between section A and the RSPF glass height adjustment resin surface (a), and close the RSPF unit. Slowly pull out the RSPF height adjustment sheet. Check to insure that a slight resistance is felt when pulling out the RSPF height adjustment sheet. * Be careful not to cover the convex section of the glass holding resin surface with the height adjustment sheet. A a Adjust hinge D until there is a resistance in section A. (Counterclockwise) Turn the hinge D to lift the RSPF so that there is a resistance in the section A. (Clockwise) b) If it cannot be pulled out, loosen the fixing nut and turn the section D clockwise to lift the RSPF unit, and make an adjustment. If it can be pulled out without resistance, loosen the fixing nut and turn the section D counterclockwise to move down the RSPF unit, and make an adjustment. D MX-M503N MX-RP11 28 - 3