Sharp MX-M363N Installation Manual - Page 13

H. Specifications setup, I. Image quality check, Copy density and gradation check - user guide

|

View all Sharp MX-M363N manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 13 highlights

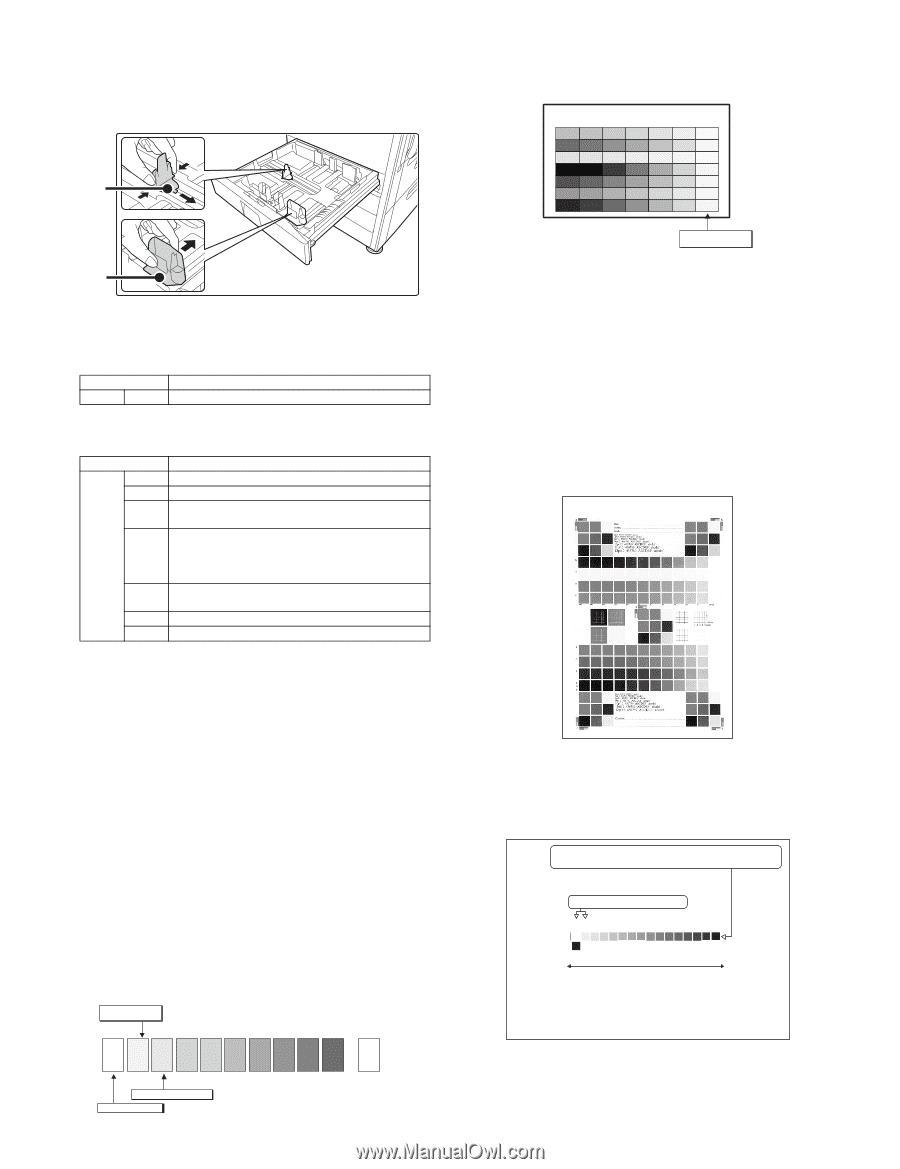

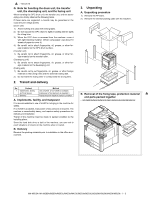

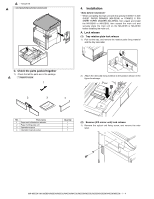

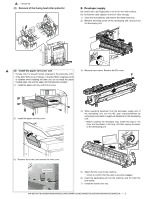

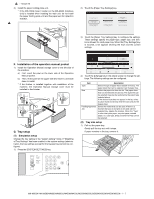

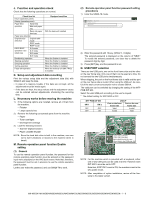

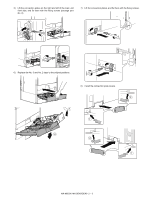

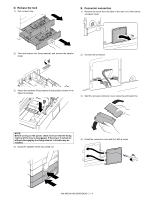

2) Adjust the guide plates A and B by squeezing their lock levers and sliding them to match the vertical and horizontal dimensions of the paper to be loaded. The guide plates A and B are slidable. Slide each guide plate while squeezing its lock lever. [Check with the servicing color test chart (UKOG-0317FCZZ/ UKOG-0317FC11 or UKOG-0326FCZZ/UKOG-0326FC11)] Check to confirm that it is in the conditions shown below. Serviceman chart (Color patch section) A Patch 7 is slightly copied or not copied. B H. Specifications setup Used to set the specifications with SIM26 according to the customer's request. SIM No 26 6 Content Used to set the destination. To customize the following items after completion of the destination setup, change the set values. SIM No 26 2 3 5 18 52 53 65 Content LCC paper size setting Used to set the auditor specification mode. Used to set the count mode of the total counter and the maintenance counter. Used to set YES/NO of the toner save mode (Only in UK and Japan versions) * For other destination versions, this setup is made by the user program. Used to set YES/NO of counting when non-print paper is passed through each counter. Used to set YES/NO of user calibration permission. Used to set the limit number of sheets for stapling. I. Image quality check (1) Copy density and gradation check (Note) Before checking the copy density and gradation, be sure to execute the following jobs. * Execute the high density image correction (Process correction) forcibly. (SIM 44-6) * Execute the half-tone image correction forcibly. (SIM 44-26) (Method) Make a copy of the gray test chart (UKOG-0162FCZZ), and check that it is proper. Note for checking the copy mode density To check the density, use the gray test chart (UKOG-0162FCZZ). Set the copy density level to "Manual 3" in the Text/Printed Photo mode (Manual). In addition, all the picture quality adjustment settings in the user adjustment mode must be set to the default (center). [Check with the gray test chart (UKOG-0162FCZZ)] In the copy density check with the gray test chart, check to insure the following conditions. (2) Printer density and gradation check If no printer option is installed to the U model, the following procedures are not required. (SIM64-5 does not operate.) (Note) Before checking the printer density and gradation, be sure to execute the following jobs. * Execute the high density image correction (Process correction) forcibly. (SIM 44-6) * Execute the half-tone image correction forcibly. (SIM 44-26) (Method 1) Execute SIM 64-5 to print the print test pattern. Set each set value to the default and press [EXECUTE] key. The print test pattern is printed. The print density must be changed gradually from the lighter level to the darker level. The density changing direction must not be reversed. (Method 2) Execute SIM 67-25 to print the adjustment check pattern. The patch density is identical between patches or not reversed. The patch density is changed gradually. PRINTER CALIBRATION Patch A or B is slightly copied. A BCDE FGH I J K LMNOP Q (Max) Low density High density Patch 2 is slightly copied. SHARP gray chart SHARP GRAY CHART 1 2 3 4 5 6 7 8 9 10 W Patch 3 is copied. Patch 1 is not copied. The print density must be changed gradually from the lighter level to the darker level. The density changing direction must not be reversed. Patch A or B is slightly copied. MX-M503N MX-M283N/M363N/M363U/M453N/M453U/M503N/M503U/M282N/M362N/M452N/M502N 1 - 8