Brother International BAS-326G PS Instruction Manual - English - Page 78

Troubleshooting

|

View all Brother International BAS-326G PS manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 78 highlights

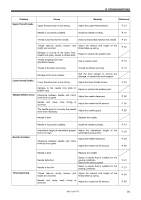

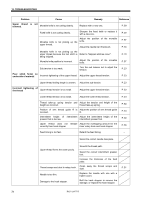

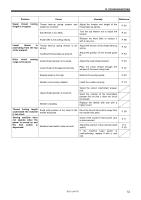

12. TROUBLESHOOTING 12. TROUBLESHOOTING • Please check the following points before calling for repairs or service. • If the following remedies do not fix the problem, turn off the power switch and consult a qualified technician or the place of purchase. CAUTION Turn off the power switch and disconnect the power cord before carrying out troubleshooting. If the foot switch is depressed by mistake, the sewing machine might start operating and injury could result. Items with a "*" in the "Reference" column should only be checked by a qualified technician. Problem Cause Remedy Reference Work clamp does not lift. Work clamp does not drop. Work clamp moves stiffly. Air tube of air cylinder is bent or damaged. Apply a suitable amount of grease to the sliding parts of the work clamp. Straighten the bend in the tube or replace the tube. Work clamp lift amount Work clamp arm lever position is Adjust the position of the work clamp is incorrect. incorrect. arm lever. Work clamp does not lift to the maximum height. Thread wiper does not operate correctly. Cylinder joint position is incorrect. The thread wiper is obstructing the needle. Adjust the position of the cylinder joint. Adjust the height of the thread wiper. Adjust the stroke of the thread wiper. P. 64 P. 61 P. 61 Thread wiper position is incorrect. Adjust the stroke of the thread wiper. Lower thread winds Bobbin winder tension assembly height Adjust the height of the bobbin winder to one side. is incorrect. tension assembly. Lower thread winding amount is incorrect. Bobbin presser position is incorrect. Adjust the position of the bobbin presser. Thread slips out of the needle. Stitches being skipped at the sewing start. Refer to "Skipped stitches occur". Upper thread trailing length is uneven. Adjust the sub tension. Thread unravelling at sewing start. Rotary hook pulls the upper thread at the sewing start. Use the programmer to reduce the intermittent presser foot height so that the upper thread is pressed by the intermittent presser foot at the 1st stitch. P. 61 P. 21 P. 21 P. 70 P. 23 * 69 BAS-326G PS