Brother International BE-1204B Stand Alone Type Instruction Manual - English - Page 144

Cleaning, 1-1 Cleaning and Lubrication of Rotary Hook

|

View all Brother International BE-1204B manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 144 highlights

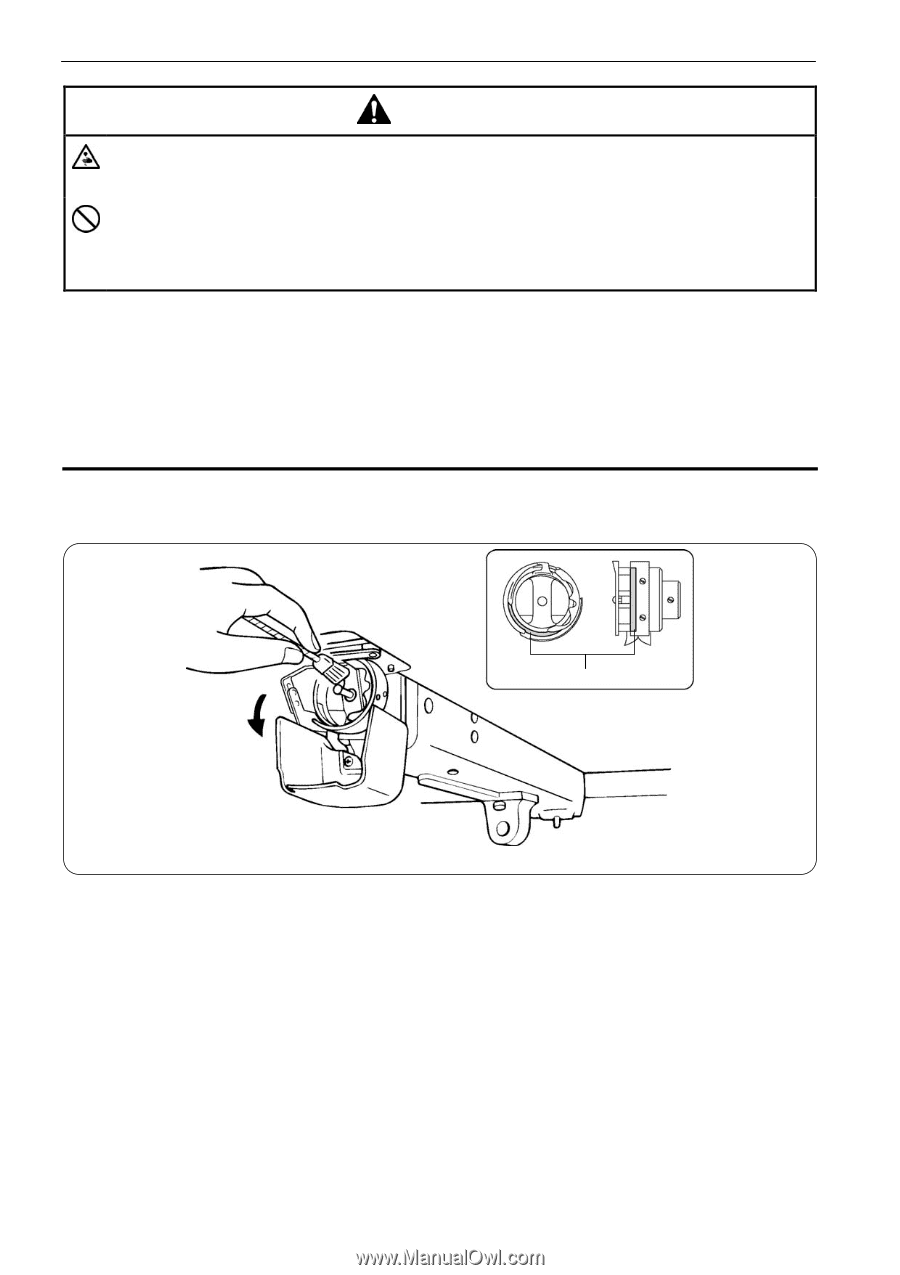

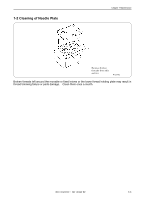

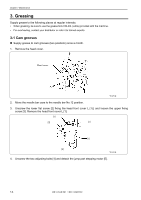

Chapter 7 Maintenance CAUTION Turn off the power switch before starting maintenance. Failure to do so may start the machine unintentionally through an accidental activation of the START switch, resulting in bodily injuries. Be sure to wear protective goggles and gloves when handling the lubricating oil or grease, so that no oil or grease gets into your eyes or onto your skin, otherwise inflammation can result. Furthermore, do not drink the oil or grease under any circumstances, as they can cause vomiting and diarrhoea. Keep the oil out of the reach of children. • Keep the machine clean at all times to prevent machine trouble. • Remove dirt with a soft, dry cloth. If necessary, clean with the detergent-soaked cloth, then wipe off the detergent with a cloth dampened with (hot) water. • Never use benzene or thinner for cleaning the machine. 1. Cleaning 1-1 Cleaning and Lubrication of Rotary Hook Lubricate these points. W1288Q • Clean rotary hooks daily using the brush provided at the time of lubrication. If a rotary hook is too dirty, cleaning with a compressor (compressed air) is recommended. • In case of thread breakage errors or noises of the rotary hook, one drop lubricate the race of the rotary hook in every 3 or 4 hours operation. • Use the dropper provided to supply oil. Use Brother's specified oil (Nippon Oil, Embroidery Lube 10N; VG10). • Supply a proper amount of oil. Any excess may stain fabrics, etc. 7-2 BE-1204B-BC • BE-1206B-BC