Brother International LK3-B430 Service Manual - Page 6

connecting

|

View all Brother International LK3-B430 manuals

Add to My Manuals

Save this manual to your list of manuals |

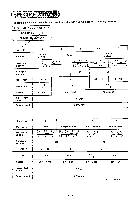

Page 6 highlights

CLUTCH MECHANISM 0 0 0 0 0 -- A ---0 _- I. When start lever 0 operates in the arrow direction, the low speed part® of ball presser plate 0. which is fixed to clutch lever 0 via connecting rod 0. gets in line with the center of steel ball 0 to convey the power to the upper shaft. 2. One end of clutch connecting rod 0 is connected toclutch lever0,and the other end toclutchactuatinglever to drive clutch cam lever 0 about clutch actuating lever shaft 0 so that roller at its end goes up on the low ®. speed part 0 of clutch cam This makes the machine sew 2 stitches at low speed from the start. ®, 3. When roller projected part goes up on the of feed came so high speed part © of clutch cam control cam lever roller ® falls from a that roller holderID comes under roller O. This makes the machine sew up to4 ® ®, stitches before the final stitch at high speed. 4. When roller goes up on a projected part of feed cam roller® is released from roller holder® to fall on the high speed part © low speed, roller of clutch cam0,and then moves onto gets into a recess of clutch cam ID. the low speed part ®. As the machine sews 4 stitches at e. (Stop When Lever) stop lver (1) is pushed in the arrow direction, roller 0 is released from roller holder 0 and gets into a recess of clutch cam -4-