Brother International LK3-B430 Service Manual - Page 8

Brother International LK3-B430 Manual

|

View all Brother International LK3-B430 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 8 highlights

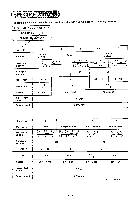

FEED MECHANISM ® •0 0 0 0-' (1) Tack Width Mechanism 1. When upper shafts turns in the arrow direction, worm wheel 0 which is connected to vertical shaft 0 rotates in the arrow direction. Change gear W 0 in mesh with the lower end of vertical shaft 0 comes into mesh with • change gear C 0 which is engaged with feed cam 0 so that feed cam 0 rotates similarly in the arrow direction. 2. Roller 0 fits in the groove of feed cam 0 to convey the rocking motion to tack width feed lever 0. Tack width regulator lever 0. which is connected to tack width feed lever 0. similarly rocks. 3. Tack width lever m is connected to tack width regulator lever 0 with nut m so that it moves feed guides back and forth about tack width lever shafts as fulcrum. (2) Tack Length/ Mechanism 4. Roller 0 fits in the groove on the underside of feed cam 0 to convey the rocking'motion to back length feed Q ® lever about tack length feed lever shaft as fulcrum. ® 0 5. Tack length regulator lever is connected to tack length feed lever with nut Q so that it rocks tack length lever Q. Similarly, slide block • fits into the slot of feed guide 0 to move feed guide sidewise. 6. The combination of the motions mentioned in Paragraphs 3 and 5 produces a sewing pattern. r, • - 6 -