Brother International LK3-B430 Service Manual - Page 7

Brother International LK3-B430 Manual

|

View all Brother International LK3-B430 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 7 highlights

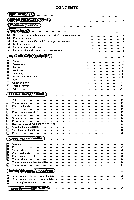

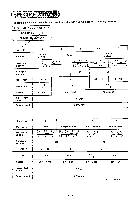

POWER WORK CLAMP LIFTER AND THREAD WIPER MECHANISMS 0- 0 010 0 C 0- 0 O (1) Power Work Clamp Lifter Mechanism I. When power actuating lever Q operates in the arrow direction, roller 0 attached to the lower end of clutch actuating lever Q is pushed up so that roller 0 disengage: from the cam part QQ of power cam 0. Thus power cam 0 contacts power pulley 0 to be driven one half of a turn. 2. Roller 0 contacts the work clamp lifter cam part @ to convey themotion toconnectingrod0 via actuatinglever shaft 0 as fulcrum. 3. Connecting rod Q is connected to connectingleverm toconvey its motion to rod A via connectinglever shaft ® al as fulcrum. 4. Rod A is connected to work clamp lifter lever to lift work clamp lifter plate ® via slide block which is fitted to work clamp lifter lever that turns about work clamp lifter lever shaft O. AFkk: ® 5. Presser arm lever which has been pushed down by work clamp lifter plate is then pushed up by presier spring ® so that work clamp ® is lowered about presser arm lever shaft as fulcrum. • 6. When work clamp lifter roller shaft ® disengages from start lever claw upon sewing the fiial stitch, roller disengages from the cam part @ so that power cam 0 half of a turn to lift work clamp O. contacts power pulley O. which drives poweecam0 one ® (2) Thread Wiper Mechanism Thread wiper rod assembly which is connected to the lower end of work clamp lifter lever conveys its motion to ® thread wiper link ® via thread wiper wiper arm 0, via thread wiper arm shaft as support fulcrum, and actuates as fulcrum. thread wiper ®, which is connected to thread • -5-