Hitachi CD14F Instruction Manual - Page 14

Warning

|

UPC - 717709006423

View all Hitachi CD14F manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 14 highlights

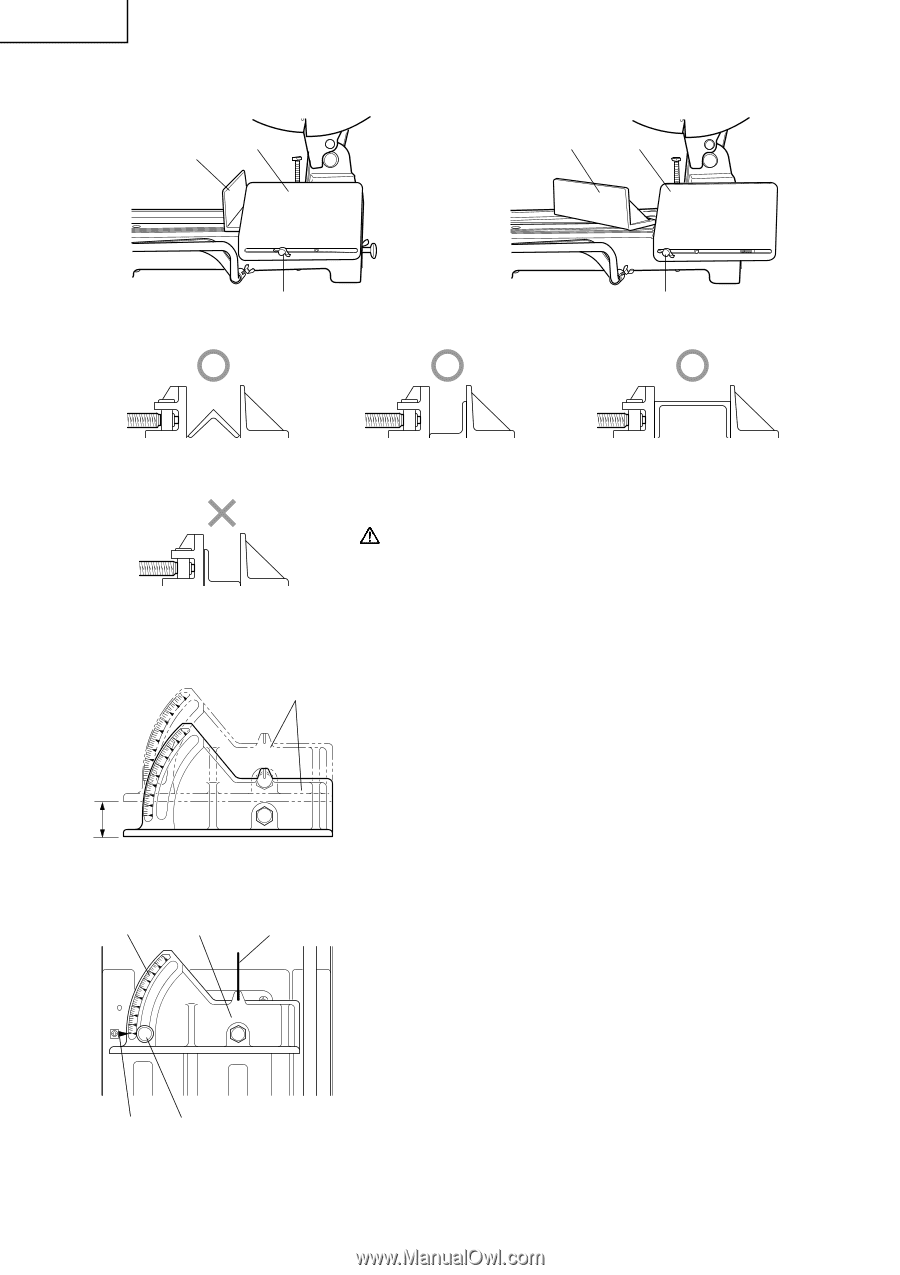

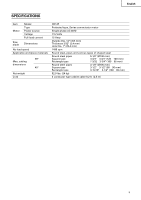

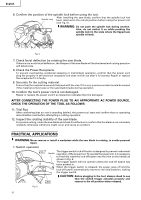

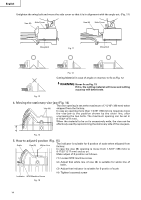

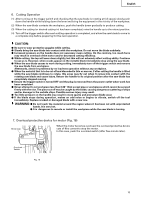

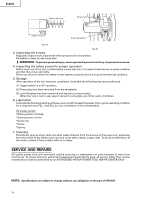

English Untighten the wing bolt and move the side cover so that it is in alignment with the angle set. (Fig. 11) Vise (B) Side Cover Vise (B) Side Cover Wing Bolt Fig. 11 Wing Bolt Fig. 12 Cutting Material in case of angle or channel, to fix as Fig. 12 WARNING: Never fix as Fig. 13 If it is, the cutting material will move and cutting accuracy will deteriorate. Fig. 13 4. Moving the stationary vise-jaw (Fig. 14) The vise opening is set at the maximum of 7-5/16" (186 mm) when Vise (B) shipped from the factory. In case an opening more than 7-5/16" (186 mm) is required, move the vise-jaw to the position shown by the chain line, after unscrewing the two bolts. The maximum opening can be set in 8-17/32" (217 mm). When the material to be cut is excessively wide, the vise can be effectively used by repositioning the stationary side of the vise jaws. Fig. 14 5. How to adjust 0 positon (Fig. 15) Scale Vise (B) White Line The indicator is suitable for 0 positon of scale when shipped from factory. In case the vise (B) opening is move from 7-5/16" (186 mm) to 8-17/32" (217 mm) and so on. Make adjust of 0 position as follows. (1) Loosen M10 machine screw (2) Adjust that white line of vise (B) is suitable for white line of base. (3) Adjust that indicator is suitable for 0 positio of scale (4) Tighten loosened screw Indicator M10 Machine Screw Fig. 15 14