Stihl MSE 210 C-BQ Instruction Manual - Page 30

Tensioning the Saw Chain, quick chain tensioner, Checking Chain Tension, Chain Lubricant

|

View all Stihl MSE 210 C-BQ manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 30 highlights

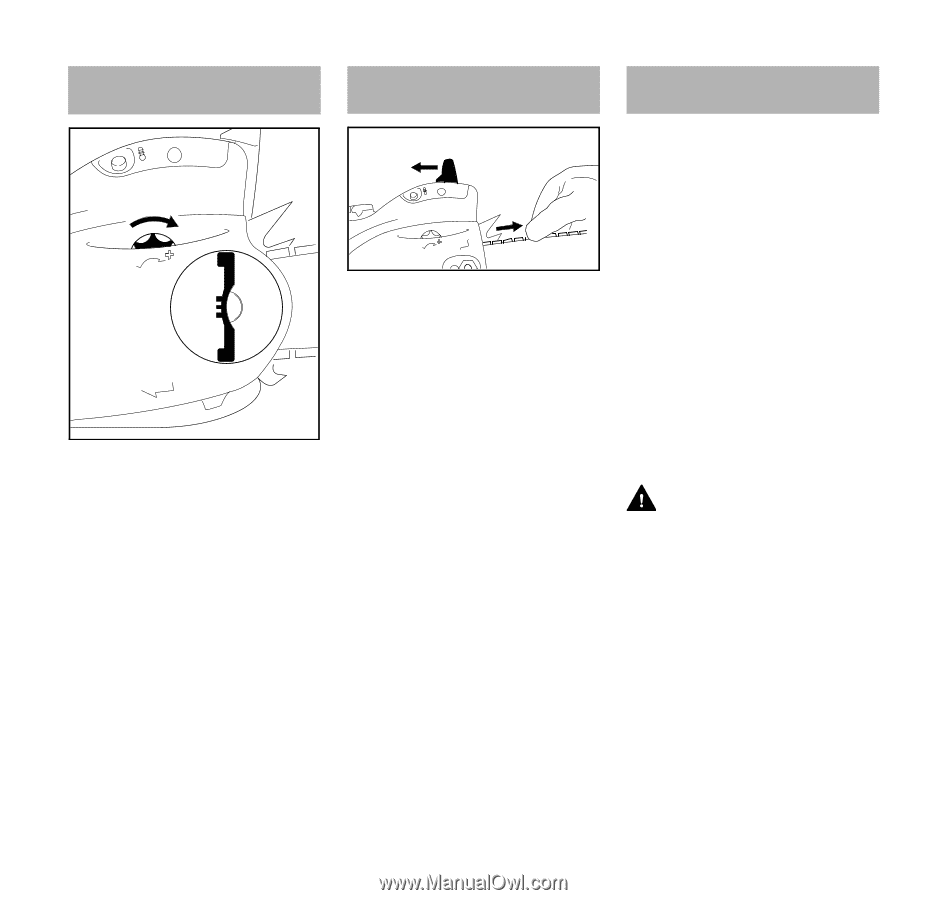

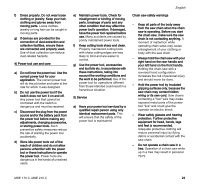

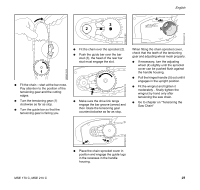

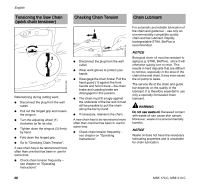

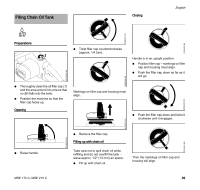

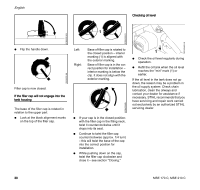

English Tensioning the Saw Chain (quick chain tensioner) 1 2 Retensioning during cutting work: N Disconnect the plug from the wall outlet. N Pull out the hinged grip and loosen the wingnut. N Turn the adjusting wheel (1) clockwise as far as stop. N Tighten down the wingnut (2) firmly by hand. N Fold down the hinged grip. N Go to "Checking Chain Tension". A new chain has to be retensioned more often than one that has been in use for some time. N Check chain tension frequently - see chapter on "Operating Instructions". 9931BA024 KN 9931BA012 KN Checking Chain Tension 1 N Disconnect the plug from the wall outlet. N Wear work gloves to protect your hands. N Disengage the chain brake: Pull the hand guard (1) against the front handle and hold it there - the chain brake and coasting brake are disengaged in this position. N The chain must fit snugly against the underside of the bar and it must still be possible to pull the chain along the bar by hand. N If necessary, retension the chain. A new chain has to be retensioned more often than one that has been in use for some time. N Check chain tension frequently - see chapter on "Operating Instructions". Chain Lubricant For automatic and reliable lubrication of the chain and guide bar - use only an environmentally compatible quality chain and bar lubricant. Rapidly biodegradable STIHL BioPlus is recommended. NOTICE Biological chain oil must be resistant to aging (e.g. STIHL BioPlus), since it will otherwise quickly turn to resin. This results in hard deposits that are difficult to remove, especially in the area of the chain drive and chain. It may even cause the oil pump to seize. The service life of the chain and guide bar depends on the quality of the lubricant. It is therefore essential to use only a specially formulated chain lubricant. WARNING Do not use waste oil. Renewed contact with waste oil can cause skin cancer. Moreover, waste oil is environmentally harmful. NOTICE Waste oil does not have the necessary lubricating properties and is unsuitable for chain lubrication. 28 MSE 170 C, MSE 210 C