Stihl MSE 210 C-BQ Instruction Manual - Page 37

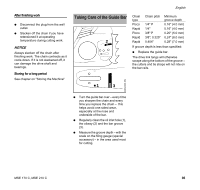

Taking Care of the Guide Bar

|

View all Stihl MSE 210 C-BQ manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 37 highlights

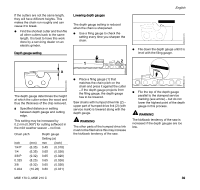

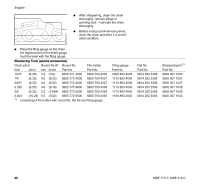

After finishing work N Disconnect the plug from the wall outlet. N Slacken off the chain if you have retensioned it at operating temperature during cutting work. NOTICE Always slacken off the chain after finishing work. The chain contracts as it cools down. If it is not slackened off, it can damage the drive shaft and bearings. Storing for a long period See chapter on "Storing the Machine" English Taking Care of the Guide Bar 2 Chain type Picco Rapid Picco Rapid Rapid Chain pitch 1/4" P 1/4" 3/8" P 3/8"; 0.325" 0.404" Minimum groove depth 0.16" (4.0 mm) 0.16" (4.0 mm) 0.20" (5.0 mm) 0.24" (6.0 mm) 0.28" (7.0 mm) If groove depth is less than specified: N Replace the guide bar. The drive link tangs will otherwise scrape along the bottom of the groove - the cutters and tie straps will not ride on the bar rails. 1 3 143BA026 KN N Turn the guide bar over - every time you sharpen the chain and every time you replace the chain - this helps avoid one-sided wear, especially at the nose and underside of the bar. N Regularly clean the oil inlet hole (1), the oilway (2) and the bar groove (3). N Measure the groove depth - with the scale on the filing gauge (special accessory) - in the area used most for cutting. MSE 170 C, MSE 210 C 35