Stihl MSE 210 C-BQ Instruction Manual - Page 40

BA025 KN, 689BA043 KN - pm3

|

View all Stihl MSE 210 C-BQ manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 40 highlights

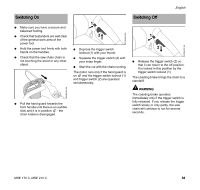

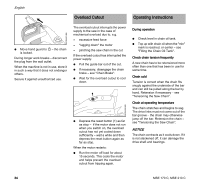

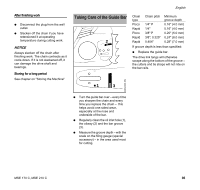

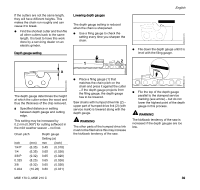

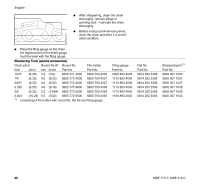

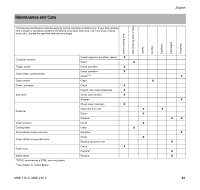

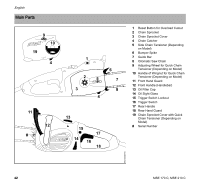

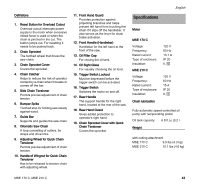

English STIHL saw chains are sharpened to a filing angle of 30°. Exceptions are ripping chains with a filing angle of 10°. Ripping chains have an X in their designations. B Side plate angle The correct side plate angle is obtained automatically if you use the prescribed file holder and file diameter. Cutter shapes Angle (°) AB Micro = semi chisel cutter, 30 75 e.g. 63 PM3, 26 RM3, 36 RM Super = chisel cutter, e.g. 30 60 63 PS3, 26 RS, 36 RS3 Ripping chain, e.g. 63 PMX, 36 RMX 10 75 The angles must be the same on all cutters. If the angles are uneven: Chain will run roughly, not in a straight line, wear quickly and finally break. File holder N Use a file holder A file holder must be used for manual resharpening (see table "Sharpening Tools"). The correct filing angles are marked on the file holder. 689BA025 KN Use only special saw chain sharpening files. Other files have the wrong shape and cut. For checking angles 90° 689BA018 KN 001BA203 KN 689BA043 KN Use a STlHL filing gauge (special accessory, see table "Sharpening Tools"). This is a universal tool for checking the filing and side plate angles, depth gauge setting, cutter length and groove depth. It also cleans the guide bar groove and oil inlet holes. File correctly N Disconnect the plug from the wall outlet. N Select sharpening tools according to chain pitch. N Clamp the bar in a vise if necessary. N To rotate the chain - pull hand guard against handle to disengage the chain brake Hold the hand guard in this position - the coasting brake is disengaged. N Sharpen the chain frequently, take away as little metal as possible - two or three strokes of the file are usually enough. N Hold the file horizontally (at a right angle to the side of the guide bar) and file according to the angles marked on the file holder. Rest the file holder on the top plate and depth gauge. N Always file from the inside to the outside of the cutter. N The file only sharpens on the forward stroke - lift the file off the cutter on the backstroke. N Avoid touching the tie straps and drive links with the file. N Rotate the file at regular intervals while filing to avoid one-sided wear. N Use a piece of hardwood to remove burrs from the cutting edge. N Check angles with the filing gauge. All cutters must be the same length. 38 MSE 170 C, MSE 210 C