Stihl MSE 210 C-BQ Instruction Manual - Page 41

service mark is lowered along with

|

View all Stihl MSE 210 C-BQ manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 41 highlights

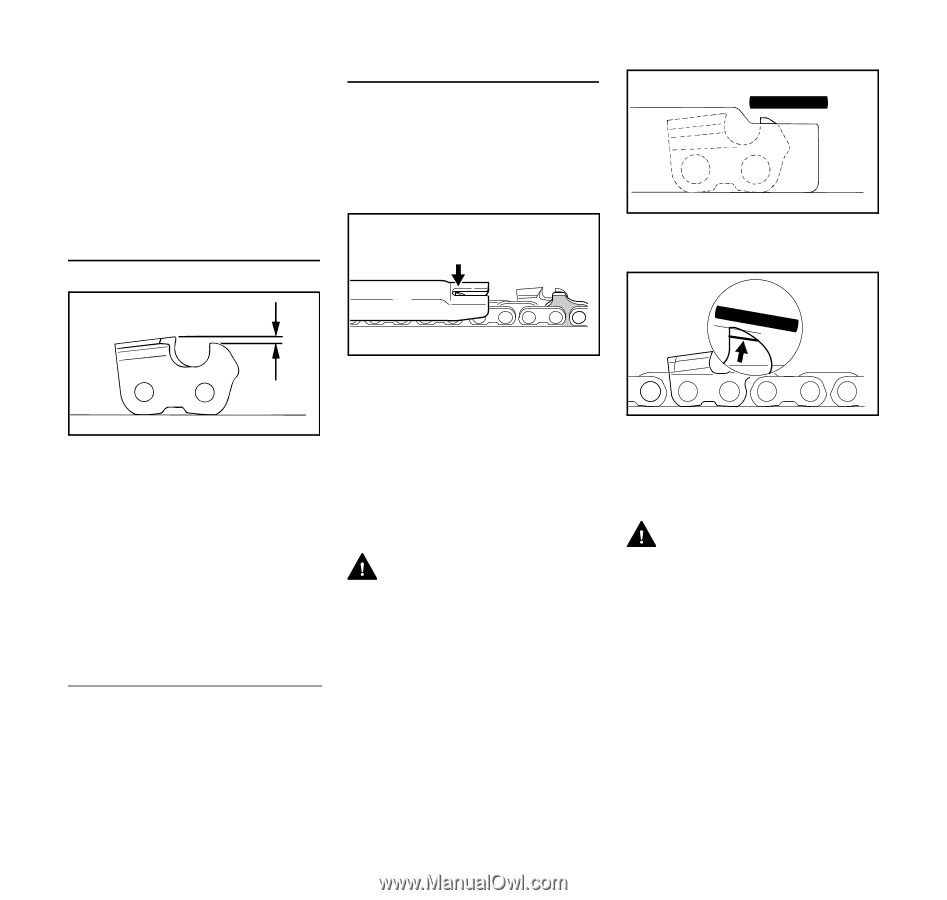

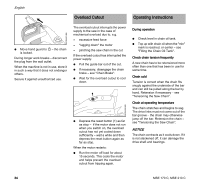

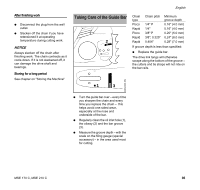

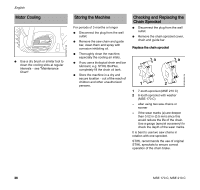

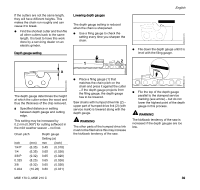

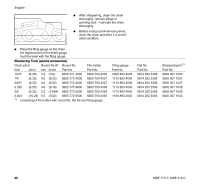

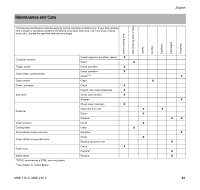

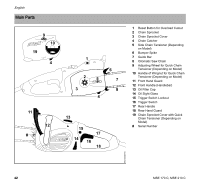

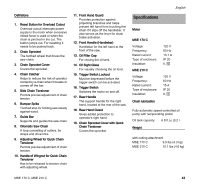

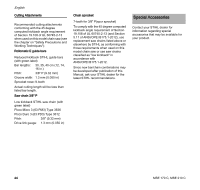

If the cutters are not the same length, they will have different heights. This makes the chain run roughly and can cause it to break. N Find the shortest cutter and then file all other cutters back to the same length. It is best to have this work done by a servicing dealer on an electric grinder. Depth gauge setting a 689BA023 KN The depth gauge determines the height at which the cutter enters the wood and thus the thickness of the chip removed. a Specified distance or setting between depth gauge and cutting edge. This setting may be increased by 0.2 mm (0.008") for cutting softwood in the mild weather season - no frost. Chain pitch inch 1/4 P 1/4 3/8 P 0.325 3/8 0.404 (mm) (6.35) (6.35) (9.32) (8.25) (9.32) (10.26) Depth gauge Setting (a) mm (inch) 0.45 (0.018) 0.65 (0.026) 0.65 (0.026) 0.65 (0.026) 0.65 (0.026) 0.80 (0.031) Lowering depth gauges The depth gauge setting is reduced when the chain is sharpened. N Use a filing gauge to check the setting every time you sharpen the chain. 1 2 N Place a filing gauge (1) that matches the chain pitch on the chain and press it against the cutter - if the depth gauge projects from the filing gauge, the depth gauge has to be lowered. Saw chains with humped drive link (2) - upper part of humped drive link (2) (with service mark) is lowered along with the depth gauge. WARNING The other parts of the humped drive link must not be filed since this may increase the kickback tendency of the saw. 689BA061 KN English N File down the depth gauge until it is level with the filing gauge. N File the top of the depth gauge parallel to the stamped service marking (see arrow) - but do not lower the highest point of the depth gauge in this process. WARNING The kickback tendency of the saw is increased if the depth gauges are too low. 689BA044 KN 689BA051 KN MSE 170 C, MSE 210 C 39