Brother International BAS-705 Instruction Manual - English - Page 3

Maintenance And Inspection, Dip Switch, Error Codes, Troubleshooting, Options, 1 Machine Head

|

View all Brother International BAS-705 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 3 highlights

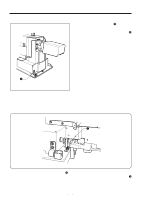

6-2-5 During sewing 54 6-3 Adjustments required when the belt loop thickness is changed 55 6-3-1 Adjusting joint sensor 55 6-3-2 Adjusting loop support T 55 6-3-3 Replacing the fork bracket and fork shafts (L and S 56 6-3-4 Adjusting the fork shaft and the belt loop transfer height 58 6-3-5 Adjusting the air pressure for cleaning away belt scraps (during V cutting 61 6-4 Adjusting the looseness of the belt loops 61 6-5 Adjusting the folding margin 62 6-6 Adjusting the folding 63 6-7 Changing the loop cutting shape (V cut or flat cut 64 6-7-1 Adjusting the air pressure for cleaning away belt scraps (during V cutting 64 6-8 Replacing the movable knife and fixed knife 65 6-9 Adjusting the belt loop and presser foot height 65 7. MAINTENANCE AND INSPECTION 66 7-1 Cleaning the rotary hook 66 7-2 Lubrication 66 7-3 Draining the oil 67 7-4 Cleaning the eye guard 67 7-5 Checking the needle 67 7-6 Cleaning the machine pulley 67 8. DIP SWITCH 68 8-1 Panel DIP switch functions 68 8-2 Main circuit board DIP switch functions 70 9. ERROR CODES 71 10. TROUBLESHOOTING 74 10-1 Machine Head 74 10-2 Mechanisms 79 11. OPTIONS 82 11-1 Hand set switch unit (S41639-001 82 11-2 Upper thread breakage detector assembly (S40520-009 83 11-3 Belt loop slackener (S43632-001 84 11-4 Loop setting sensor (S41959-001 85 11-5 Clipping disposal funnel assembly (S41906-001 86