Brother International BAS-705 Instruction Manual - English - Page 79

Refer to Skipped, raise the height of

|

View all Brother International BAS-705 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 79 highlights

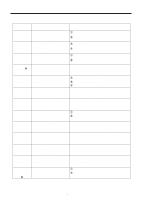

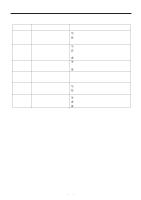

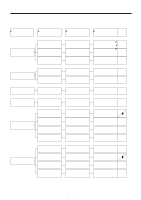

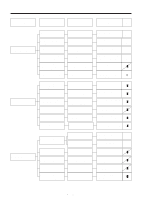

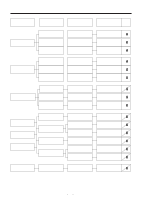

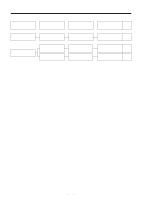

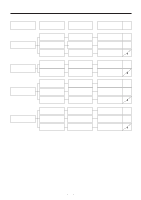

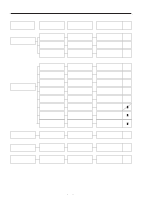

10. TROUBLESHOOTING Problem Cause Check Remedy Page Upper thread is not trimmed. Fixed knife is blunt. Movable knife does not pick up the thread. The movable knife does not pick up the thread because of skipped stitches at the sewing end. Movable knife position is incorrect. Sub-tension is too weak. Fixed knife blade Shuttle race thread guide position Needle bar lift amount Skipped stitches at sewing end Movable knife position Sub-tension Sharpen or replace the fixed knife. Adjust the position of the shuttle race thread guide. 40 Adjust the needle bar lift amount. 37 Refer to "Skipped stitches occur". Adjust the position of the movable knife. 40 Turn the sub-tension nut to adjust the tension. 28 Thread jamming. Thread jamming at the final stitch. Upper thread breaks at the final stitch. Thread trailing length is too long. Sub-tension Thread take-up spring tension and height are incorrect. Incorrect needle and rotary hook timing. Shuttle race thread guide is not separating the threads. Thread scraps sticking to surface of race. Upper tension is too weak. Too much thread. Thread take-up spring tension and height Needle bar lift amount Shuttle race thread guide position Surface of shuttle hook Upper tension Thread amount Incorrect height or tension of thread take-up spring. Tension and height of thread take-up spring Incorrect thread release cylinder operation. Sub-tension is too strong. Thread release cylinder operation Sub-tension Thread take-up spring tension and height are incorrect. Damaged or burred shuttle race, needle hole plate, needle, movable knife or shuttle race thread guide. Thread take-up spring tension and height Damage or burring ʕ 76 ʕ Thread resistance along 28 thread path is too small. Adjust the thread trailing length to 45 mm. 28 Adjust the tension and height of the thread 29 take-up spring. Adjust the needle bar lift amount. 37 Adjust the position of the shuttle race thread guide. 40 Clean all thread scraps and dust from the race 66 Make the upper tension stronger. 28 Reduce the thread amount. 28 Decrease the tension or raise the height of the 29 thread take-up spring. Adjust the thread release cylinder so that it operates smoothly. Decrease the subtension. 28 Decrease the tension or raise the height of the 29 thread take-up spring. File smooth or replace the affected part. B A S -705