Brother International BAS-705 Instruction Manual - English - Page 83

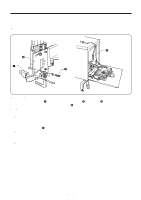

the fork shafts., picked up correctly.

|

View all Brother International BAS-705 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 83 highlights

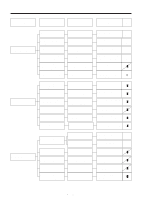

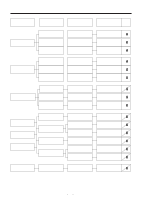

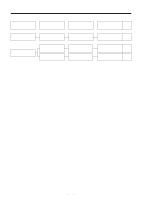

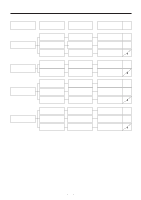

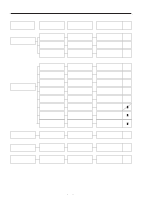

10. TROUBLESHOOTING Problem Cause Check Remedy Page Belt loops are not being fed. A joint is caught in the channel. Joints are not being detected. Incorrect joint sensor position. Channel width Joint sensor position Adjust the channel width. 52 Adjust the joint sensor. 55 Joints are not removed. Air pressure is too low. Air pressure check Adjust the air pressure. 64 The belt loops are not being held properly by the fork shafts. The belt loops are not being held properly by the loop pressers. Belt loops are not being picked up correctly. Distance between fork shafts is not suitable for belt thickness. Distance between button presser A and the loop pressers is not correct. Incorrect belt loop and fork shaft alignment position. Distance between fork shafts is not suitable for belt thickness. Distance between fork shafts and belt loop thickness Distance between button presser A and loop pressers Belt loop and fork shaft timing during belt loop pick-up Distance between fork shafts and belt loop thickness Replace with an appropriate fork bracket. 56 Adjust the positions of the loop pressers. 58 Adjust the belt loop transfer height. 58 Replace the fork bracket (assembly). 56 V cutting does not occur. Knife stopper is stopping knife rotation base 2. DIP switch has not been changed before power was turned on. Tilt of knife stopper DIP switch Change the tilt of the knife stopper. 64 Turn the power back on. 64 Cutter does not cut properly. Worn cutter knife Cutting surface of belt loops Replace the knife. 65 Loops are not fed at joints. Loops are riding over feed roller guide. Feed roller guide position Raise the rear of the feed roller guide. ʕ 80 ʕ B A S -705