Brother International SE-400 Users Manual - English - Page 155

Otherwise, the upper thread may become

|

View all Brother International SE-400 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 155 highlights

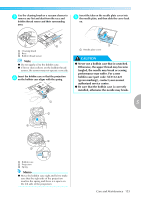

Use the cleaning brush or a vacuum cleaner to g remove any lint and dust from the race and bobbin thread sensor and their surrounding area. Insert the tabs on the needle plate cover into i the needle plate, and then slide the cover back on. a c b a Cleaning brush b Race c Bobbin thread sensor Note z Do not apply oil to the bobbin case. z If lint or dust collects on the bobbin thread sensor, the sensor may not operate correctly. Insert the bobbin case so that the projection h on the bobbin case aligns with the spring. a a Needle plate cover CAUTION ● Never use a bobbin case that is scratched. Otherwise, the upper thread may become tangled, the needle may break or sewing performance may suffer. For a new bobbin case (part code: XC3152-221 (green marking)), contact your nearest authorized service center. ● Be sure that the bobbin case is correctly installed, otherwise the needle may break. a 5 b c c b a Bobbin case b Projection c Spring Memo z Move the bobbin case right and left to make sure that the right side of the projection touches the spring and there is a space on the left side of the projection. Care and Maintenance 153