Brother International SE-400 Users Manual - English - Page 159

in the bobbin case.

|

View all Brother International SE-400 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 159 highlights

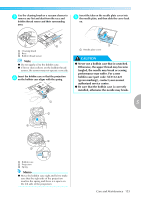

Symptom Probable Cause Remedy Reference Stitches are skipped. The needle is incorrectly installed. Correctly install the needle. Dust has accumulated under the Remove the needle plate cover and needle plate or in the bobbin case. clean the race. page 41 page 152 Dust has accumulated in the feed dogs or in the bobbin case. Clean the race. page 152 A high-pitched noise is made while sewing. The upper thread was not threaded correctly. The bobbin case is scratched, or has a burr on it. Correct the upper threading. Replace the bobbin case. Contact your dealer or the nearest authorized service center. page 32 - A bobbin designed specifically for this machine is not used. Incorrect bobbins will not work properly. Only use a bobbin designed specifically for this machine. page 22 The thread does not pass through the eye of the needle. The needle has not been raised to the correct position. Press the needle position button. The needle is incorrectly installed. Correctly install the needle. page 32 page 41 The presser foot that is used is not Attach the presser foot that is appropriate for the type of stitch appropriate for the type of stitch that that you wish to sew. you wish to sew. page 70 The stitch is not sewn correctly. The thread tension is incorrect. Adjust the tension of the upper thread. page 59 The thread is tangled, for example, in the bobbin case. Remove the tangle thread. If the thread is tangled in the bobbin case, clean the race. page 152 5 The feed dogs are lowered. Slide the drop feed lever to the right. page 102 The stitch is too fine. Lengthen the stitch length. page 59 The fabric does not feed. The presser foot that is used is not appropriate for the type of stitch that you wish to sew. Attach the presser foot that is appropriate for the type of stitch that you wish to sew. page 70 The thread is tangled, for example, in the bobbin case. Remove the tangled thread. If the thread is tangled in the bobbin case, clean the race. page 152 The fabric feeds in the opposite The feed mechanism is damaged. direction. Contact your dealer or the nearest authorized service center. - The needle threader lever does The needle has not been raised to not lower to the the correct position. correct position. Press the needle position button. page 32 The sewing lamp The sewing lamp is damaged. does not come on. The machine is not turned on. Contact your dealer or the nearest authorized service center. Turn on the machine. page 17 Nothing appears in the LCD. The brightness of the LCD is either too light or too dark. Adjust the brightness of the LCD. page 163 Troubleshooting 157