Brother International Innov-is NS80e Operation Manual - Page 7

Getting Ready

|

View all Brother International Innov-is NS80e manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 7 highlights

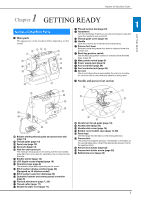

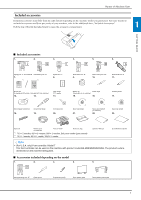

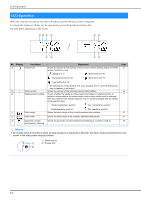

Names of Machine Parts 1 Chapter GETTING READY Names of Machine Parts ■ Main parts The appearance of the machine differs depending on the model. b cde a o n m f g h i j l p k q r s E Thread tension dial (page 27) F Handwheel Turn the handwheel toward you (counterclockwise) to raise and lower the needle to sew one stitch. G Thread guide cover (page 13) H Handle Carry the machine by its handle when transporting. I Presser foot lever Raise and lower the presser foot lever to raise and lower the presser foot. J Feed dog position switch Use the feed dog position switch to raise and lower the feed dogs. (page 48) K Main power switch (page 9) L Power supply jack (page 9) M Foot controller (page 24) N Foot controller jack (page 24) O Air vent The air vent allows the air surrounding the motor to circulate. Do not cover the air vent while the machine is being used. ■ Needle and presser foot section i a h b GETTING READY 1 t y x u v w 1 Bobbin winding thread guide and pretension disk (page 13) 2 Thread guide (page 13) 3 Spool cap (page 12) 4 Spool pin (page 12) 5 Hole for extra spool pin This holds an extra spool pin for sewing with the twin needle. (page 52) This is not a hole for lubrication. Do not insert oil into this hole. 6 Bobbin winder (page 12) 7 LCD (liquid crystal display) (page 10) 8 Operation keys (page 6) The operation keys differ depending on the model. 9 Stitch pattern display window (page 23) (Equipped on 16 stitches model) 0 Stitch pattern selection dial (page 23) A Operation buttons and sewing speed controller (page 6) B Flat bed attachment (page 7, 29) C Thread cutter (page 17) D Needle threader lever (page 17) g c f d e 1 Needle bar thread guide (page 16) 2 Needle plate (page 29) 3 Needle plate cover (page 14) 4 Bobbin cover/bobbin case (page 14, 56) 5 Feed dogs The feed dogs feed the fabric in the sewing direction. 6 Presser foot The presser foot applies pressure consistently on the fabric as the sewing takes place. Attach the appropriate presser foot for the selected stitch. 7 Presser foot holder (page 22) 8 Presser foot holder screw (page 22) 9 Buttonhole lever (page 42) 5