Campbell Scientific IRGASON IRGASON Integrated CO2/H2O Open-Path Gas Analyzer - Page 38

Gas-Analyzer Window Cleaning, 9.4 Zero and Span, Gas-Analyzer, Window Cleaning

|

View all Campbell Scientific IRGASON manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 38 highlights

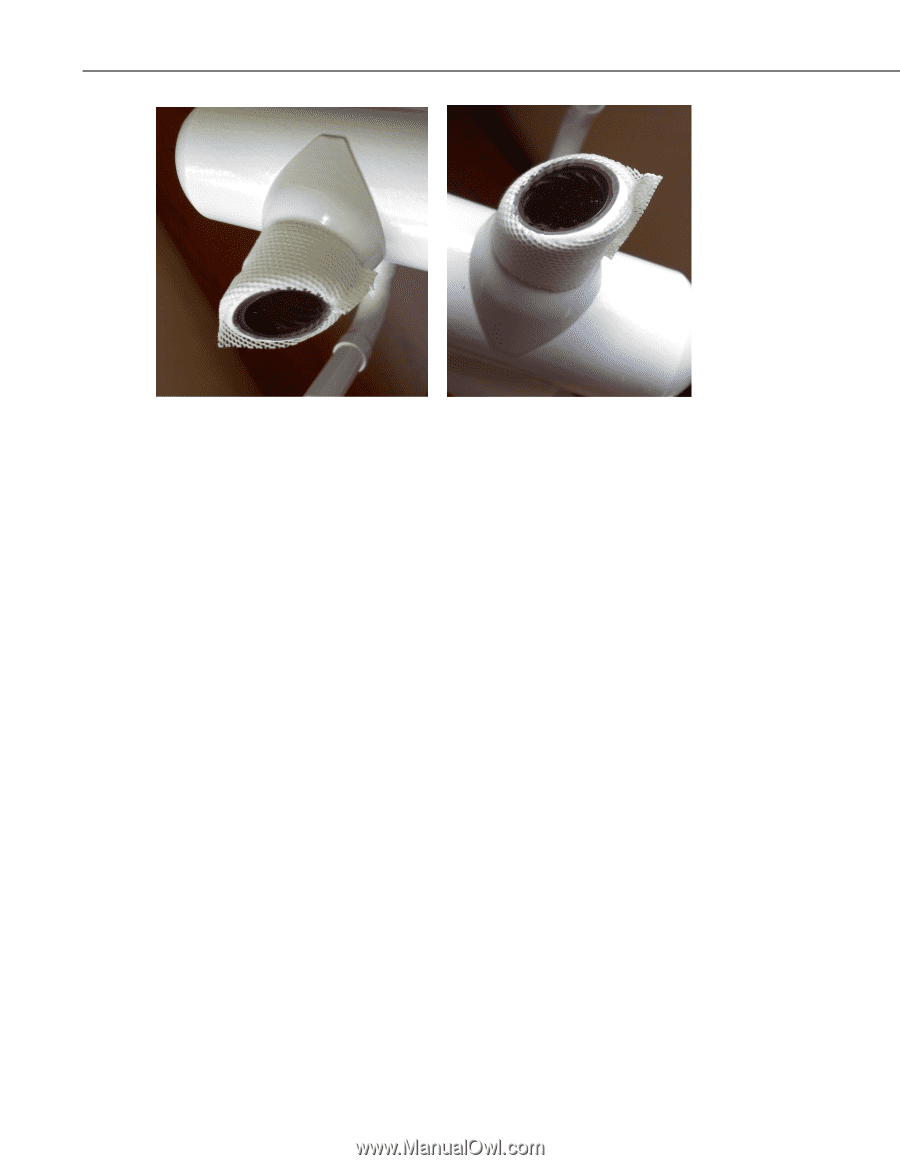

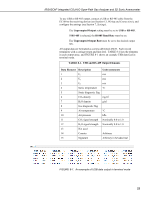

IRGASON® Integrated CO2/H2O Open-Path Gas Analyzer and 3D Sonic Anemometer FIGURE 9-3. Proper location of the gas analyzer top wick (left) and bottom wick (right) 9.3 Gas-Analyzer Window Cleaning The windows of the analyzer should be cleaned if the signal strength for CO2 or H2O drops below 0.7 or 70% of the original value. These values may be monitored in the output data, or they can be viewed with ECMon. To clean the windows, use isopropyl alcohol (2-propanol / isopropanol) and a cotton swab or a non-scratching tissue or cloth. Verify that following cleaning the signal strengths are restored to values close to 1.0. 9.4 Zero and Span As is the case with all optical instruments, the IRGASON's gas analyzer measurements may drift slightly with exposure to natural elements. Therefore, routine maintenance requires a periodic zero-and-span procedure. The frequency with which this should be done is heavily dependent on the environmental conditions in which the instrument is making measurements. Campbell Scientific recommends that a new instrument, or an instrument that has been moved to a new location, should have a monthly zero and span procedure performed. Additionally, it is recommended to always zero and span the analyzer after cleaning the windows (see Section 9.3, Gas-Analyzer Window Cleaning). After the first several zero-and-span procedures, the rate of drift in gain and offset (explained later in this section) will be better understood for the existing environmental conditions. A regimented protocol for zero and span of the instrument initially, will allow the user to assess the appropriate time interval between zero and span procedures. However, if the IRGASON is being used at a site with large seasonal changes in ambient conditions, the zero-and-span procedure should be done at least seasonally. In situations in which spanning the instrument is extremely difficult (for example, in below freezing temperature conditions or in very remote sites), performing a monthly zero will help mitigate the drift in the analyzer's measurements. 28