Dewalt DCFS950P2 Instruction Manual - Page 19

Staple Specifications

|

View all Dewalt DCFS950P2 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 19 highlights

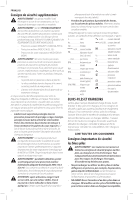

SYMPTOM Tool operates, but no staple is driven. Jammed staples. CAUSE Debris in nosepiece. Debris in magazine. Damaged pusher spring. Worn magazine. Damaged or worn driver. Incorrect staples. Magazine not secured after previous jam clear/ inspection. Material and staple length. Debris in nosepiece. Worn magazine. Tool is not yet run-in. Staples do not fit. Staple drives too deep. Staple bends. Confirm DeWALT staples are being used. Power setting too high. Depth adjust setting incorrect. Staple hit knot in wood. English FIX Clean nose area and watch closely for small pieces of broken staples stuck in the track. Clean magazine. Replace spring. See authorized service center. Replace magazine. See authorized service center. Replace driver with kit, or see authorized service center. Use only the recommended staples. Refer to Staple Specifications. Make sure to magazine is latched properly. If the unit continues to stall (forcing the need to rotate the Stall release lever) choose the appropriate material and staple length that is not too rigorous an application. Clean nose area and watch closely for small pieces of broken staples stuck in the track. Replace magazine. See authorized service center. New tools can take 100-500 staples for parts to mesh and wear in together. Drive shorter staples during this period if experiencing difficulty fully driving staples. Your fencing stapler is only compatable with DeWALT staples. Select lower power setting. Adjust tool free depth adjust dial. Move 3" (76 mm) and try again. 17