Oki OKIPOS 407II ParallelBlack Users Guide - Page 42

Reliability Specifications

|

View all Oki OKIPOS 407II ParallelBlack manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 42 highlights

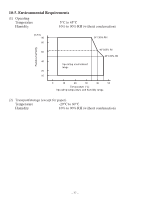

10-6. Reliability Specifications (1) MCBF: 60 million lines • Recommended thermal paper (60 μm to 75 μm) • Average printing rate: 12.5% • Printing density: standard setting Note: The Mean Cycles Before Failure (MCBF) with the recommended thermal paper thickness between 75 μm and 150 μm is 25 million lines. (2) Auto cutter (life) Paper width 82.5 mm, 79.5 mm *Including backing paper • Paper thickness between 65 μm and 100 μm: 2 million partial cuts, 1.6 million full cuts • Paper thickness between 100 μm and 150 μm: 600,000 cuts both partial and full Paper width 57.5 mm • Paper thickness between 65 μm and 85 μm: 600,000 partial cuts, 500,000 full cuts Paper width 82.5 mm, 79.5 mm full-face thermal label paper • Paper thickness between 100 μm and 150 μm: 300,000 cuts both partial and full Notes: 1) When using full-face thermal label paper, periodically clean the glue that may have accumulated on the cutter blade. 2) If glue has accumulated on the cutter blade, it could adversely affect cutting perform- ance. * A cutter is said to have reached its life when it has entered the wear failure pe- riod. * The figures indicated in the reliability specifications above are based on the use of recommended thermal paper. As such, reliability is not guaranteed if non-recommended thermal paper is used. - 38 -